Result description

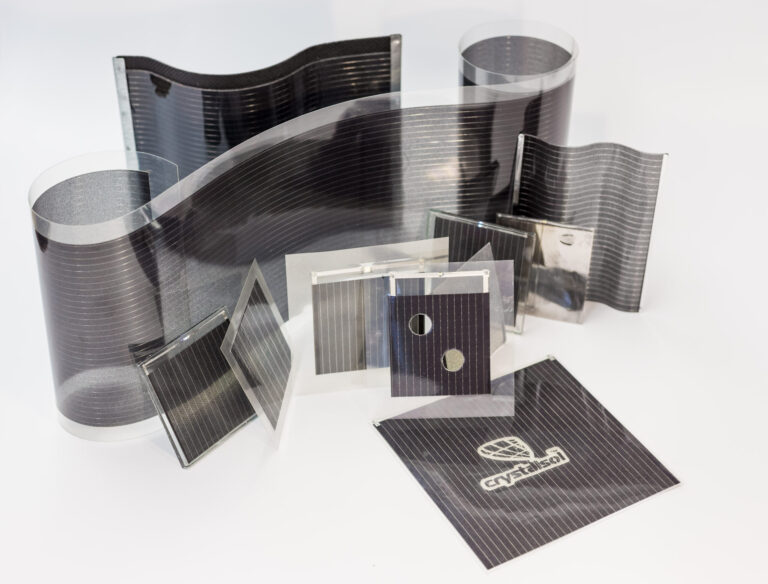

Crystalsol has developed and patented a new and innovative photovoltaics (PV) technology in which CZTSSe microcrystals, so-called monograins, are embedded in a polymer matrix. All printing processes including the deposition of the front contact are realized in a cost-effective vacuum-free roll-to-roll (R2R) process which is ready for scale-up. Only low-cost earth-abundant material without any rare or toxic elements are used and a circular economy concept for reusing the monograins is developed. Crystalsol’s PV modules are bendable, light-weight, semitransparent and can be customized to any size and color making them ideal for product integrated PV (PIPV), building integrated PV (BIPV), agrivoltaics, vehicle integrated PV (VIPV) and IoT devices.

In respect to crystalsol’s monograin layer (MGL) technology using a flexible polymer substrate several milestones could be achieved concerning up-scaling during the CustomArt project, which are listed below:

- Successful up-scaling of powder production from 30g to 1kg batch

- Demonstration of R2R vacuum-free front contact deposition with a web speed of up to 1m/min. by using chemical bath deposition (CBD) for a module with a dimension of 2000×20 cm2 with a sheet resistance of 6.06 Ω/sq and a standard deviation of 0.42 Ω/sq

- Demonstration of the compatibility of the CBD process for flexible steel substrates

Addressing target audiences and expressing needs

- Business partners – SMEs, Entrepreneurs, Large Corporations

- Business Angels

- Venture Capital

Investors/Funds for building-up an up-scaled fabrication facility and business partners who are interested to integrate our technology into their products, buildings or vehicles.

- Other Actors who can help us fulfil our market potential

- Research and Technology Organisations

- Private Investors

R&D, Technology and Innovation aspects

All printing processes for PV module fabrication including the deposition of the front contact reached TRL7 for R2R demonstrators. Next steps are finding investors for IEC certification and up-scaling of the production line. Further, licensing to business partners is targeted who are interested to integrate our PV into their products or want to use our vacuum-free R2R production technology.

Scalability of the powder production is demonstrated and a concept for industrial scale-up is developed. Furthermore, used R2R processes are known for their high scalability and low production costs decreasing the price for module production while increasing their sustainability.

Since R2R is are continuous production technology a high amount of replicability is achieved. This is already demonstrated in the printing industry where R2R processes led to drastic increase in speed and replicability while reducing production costs. Furthermore, it was shown in the CustomArt project that the R2R CBD process for the deposition of the front contact is compatible with steel substrates as well and is not limited to polymeric substrates.

Sustainability of crystalsol’s PV technology is achieved by:

- No rare or toxic materials

- Efficient low-cost and vacuum-free R2R production process avoiding waste and high energy consumption

- Circular environment concept for reusing the monograins

- Production of green energy while featuring a high degree of integrability

- Europe

- Global

Result submitted to Horizon Results Platform by CRYSTALSOL OU