High-precision coatings are required for a wide range of applications in the area of optics, electronics and sensor technology, solar energy and biomedical technology. Stationary magnetron sputtering processes being long-time stable allow the deposition of high precision, homogeneous and reproducible layers at efficient rates.

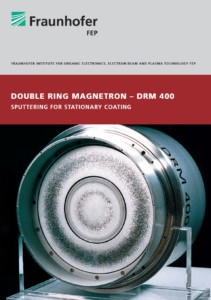

At Fraunhofer FEP we have developed a coating system based on the Double Ring Magnetron DRM 400 that can be integrated in Cluster-type plants and that can prospectively be scaled up to multi-ring magnetron sources. Individually controllable concentric plasma discharges from the inner and outer ring systems allow layer thickness homogeneities of up to ± 0.5 percent (for substrate sizes of 8″ / 200 mm) to

be achieved. Innovative control concepts are also opening new processing options such

as the deposition of gradient layers by changing the composition of the reactive gas during the coating process.

Our offer

- application-oriented process development of layer systems with customer specific requirements

- feasibility studies

- technology packages with process development and key components

- technology transfer

- retrofit of coating equipment