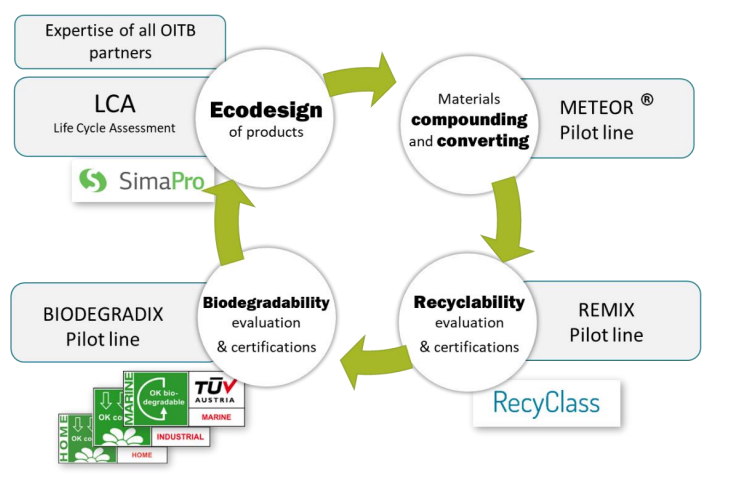

FlexFunction2Sustain Circularity-by-Design Services and Facilities

Eco-Design Services: FlexFunction2Sustain integrates “Circularity by Design” into its service offering, providing expertise in sustainable product design and Life Cycle Assessment (LCA) tools. The services cover the development and testing of eco-friendly materials, ensuring compliance with international standards.

Advanced Processing Facilities: The METEOR® Pilot Line offers innovative compounding and recycling services. The unique extensional flow mixing technology allows the efficient dispersion of additives while minimizing thermal degradation. The High-Shear Rate Mixing Unit and Slot-Die Coating systems further support the development of advanced material formulations for various applications.

Recyclability Assessment: The upgraded REMIX Pilot Line provides comprehensive recyclability testing, including optical sorting, shredding, washing, flotation, extrusion, and cast-film extrusion. This line supports the full recycling assessment process, enabling certification by RecyClass, a recognized authority in sustainable plastic packaging.

Biodegradability Testing: The BIODEGRADIX Pilot Line evaluates materials’ biodegradability in industrial and home compost environments and marine settings. The assessment includes biodegradation, disintegration, and ecotoxicity tests, with accreditation from TÜV Austria to certify products as biodegradable and compostable.

FlexFunction2Sustain is well-equipped to help SME and industries design innovative, sustainable products. From material formulation to recyclability and biodegradability assessments, the project’s facilities and expertise offer the necessary services to bring eco-friendly products to market swiftly and confidently.