Additive manufacturing (AM), also known as 3D printing, is a revolutionary process that builds threedimensional objects by adding material layer by layer. In just a decade, it swiftly evolved from a niche use for prototyping to a disruptive force impacting value chains in a growing number of industries. On-going progress in AM technologies keeps expanding the range of opportunities for enhanced customisation, improved production efficiencies and complex designs in those industries. This study uses patent data to shed light on those innovations, thus providing early insights into the forces shaping the future of AM; moreover, the data is vital for understanding the progress of AM and identifying key players driving advancements. Data from patent applications provides valuable insights into AM innovation trends, and this innovation study analyses international patent families (IPFs) to shed light on the current state of AM innovation.

Key findings of the report are:

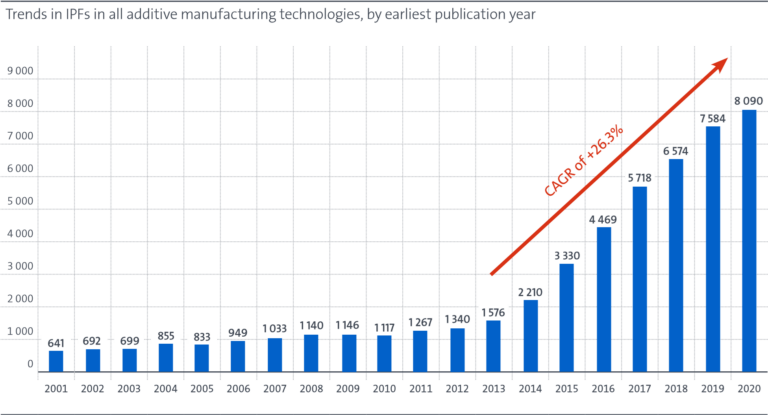

1. Impressive rise of AM innovation

Patent applications from over 50 000 international patent families (IPFs) related to AM technologies have been filed across the world since 2001. Since 2013, their number has surpassed the 2 000 mark annually, with a remarkable compound annual growth rate (CAGR) over 26% over that period (that is eight times the CAGR for patenting overall). Patent applications for more than 8 090 AM-related IPFs were published in 2020 alone, accounting for over 2% of all IPFs.

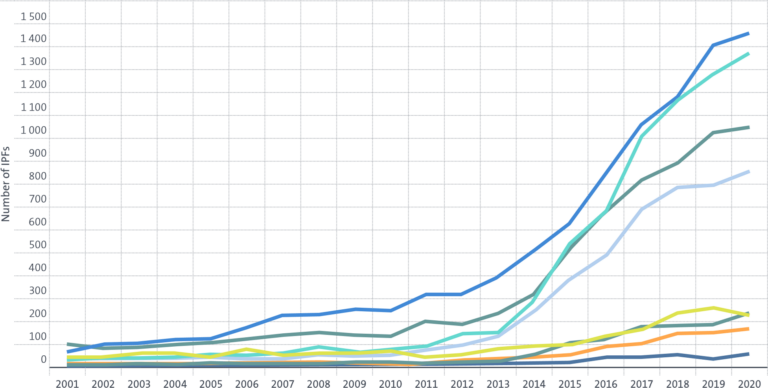

2. Adoption highest in health, medical, and transportation

While AM has long been instrumental in prototyping, it is now increasingly viable for mass customisation and even serial production. It has gained significant traction in sectors such as health and medical, and transportation (including both aerospace and automotive). In the health and medical sector alone, there were nearly 10 000 IPFs published between 2001 and 2020, as AM’s capabilities prove particularly advantageous for patient-specific implants, anatomical models and dental applications. With over 7 000 IPFs, the transportation sector is also witnessing the benefits of AM for product development and advancing toward serial production. Furthermore, valuable applications are emerging in industries like fashion, electronics, construction and even food.

3. Europe and the US are driving AM innovation

Europe and the US are leading the global race for AM innovation. The US holds the top spot, with 40% of all IPFs related to AM recorded between 2001 and 2020. Europe (EU countries and EPO member states) closely follows with a 33% share. Together, these regions account for an impressive 73% of worldwide AM innovation. In comparison, China and South Korea’s contributions remain relatively small at 4% and 3%, respectively. Within Europe, Germany is the strongest contributor, representing 41% of Europe’s share, while France has emerged as a notable player with a 12% contribution.

4. US, European and Japanese companies are in the lead

The analysis reveals that the list of top 20 applicants in AM innovation consists of six US players, seven European companies, six Japanese and one Korean company. Among them, General Electric, Raytheon Technologies, and HP stand out as the companies with the highest number of IPFs between 2001 and 2020. Siemens secures fourth position and emerges as the strongest player from Europe, boasting almost 1 000 IPFs. Although the list of top applicants is dominated by large, international companies from various industry sectors, it also includes several established 3D printing firms and emerging start-ups further down the list. This composition illustrates the rich and diverse landscape of contributors that are actively shaping AM innovation.

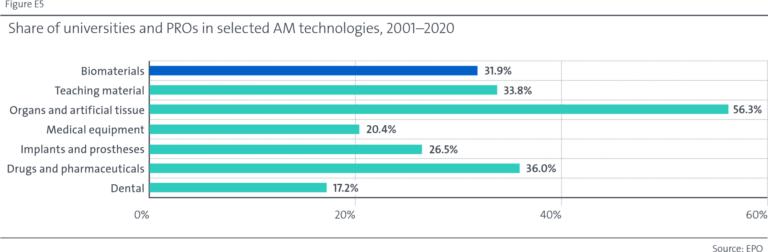

5. Strong presence of universities and research organisations (RTOs)

A remarkably high share (approximately 12%) of IPFs in AM technology have universities and public research organisations (PROs) as applicants, indicating their substantial involvement in advancing the field. However, the presence of universities and PROs varies across different AM technology areas. Particularly in the application domains related to health and medical, their contributions are noteworthy. A university or PRO is behind one in three IPFs associated with biomaterial developments and one in two IPFs for 3D printing of organs and artificial tissue. Their involvement not only enriches the knowledge base, but also fosters groundbreaking advancements in materials, processes and applications within the AM domain and provides a basis for technology start-ups with high growth potential.