The Dauerpower project, led by Fraunhofer IZM with partners from the automotive industry, aims to enhance electric vehicle performance by developing a highly efficient inverter. Overheating inverters typically limit drivetrain performance and require active cooling. This project focuses on optimized cooling management to lower operating temperatures, reduce power loss, and extend full-load utilization, thereby decreasing costs. The new inverter, developed with Porsche and Bosch, boasts a continuous output of 720 kW (979 hp) and a rated current of 900 A, achieving a 20-30% performance increase over traditional silicon-based inverters.

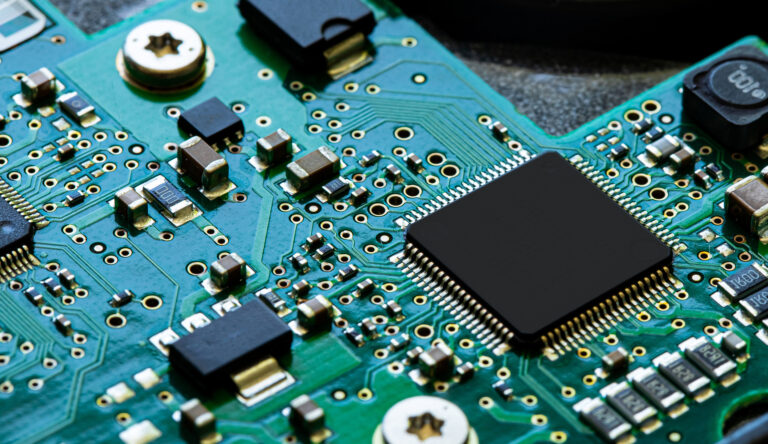

This improvement is driven by advanced materials and innovative embedding processes. The inverter uses silicon carbide transistors, which offer better efficiency and heat resistance than silicon. These transistors are prepackaged and embedded in PCBs, reducing mechanical stress and improving thermal performance. Additionally, 3D-printed copper cooling elements enhance thermal conductivity and flexibility in design, further optimizing cooling.

The modular design of the inverter allows for easier replacement and repair of components, contributing to resource-efficient production and longer vehicle operation. The prototype, currently under construction, will undergo extensive testing at Porsche. The project, funded by the German Federal Ministry of Economics, began in 2021 and involves collaboration with Porsche and Bosch.

Read the full news article here.