Natural materials including farm waste can make autos and other industries more sustainable, less toxic.

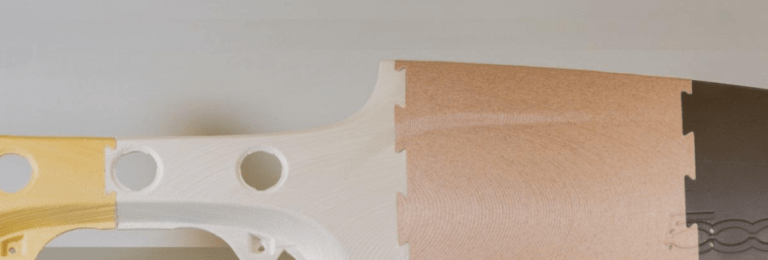

The BARBARA project, a collaborative effort between the EU and the private sector, has paved the way for innovative solutions in the European bioeconomy by utilizing agricultural residues like lemon peel, corn starch, almond shells, and pomegranate skins to create high-performance industrial materials. These materials were used as additives for biopolymers, which are naturally occurring in living organisms and can be employed in manufacturing. The project successfully produced prototypes of car parts and construction molds using 3D printing technology.

One of the most significant outcomes of the BARBARA project is the transformation of waste into valuable resources. This approach aligns with the European Union’s efforts to reduce waste, cut carbon emissions, and enhance the safety of industrial goods. The EU bioeconomy has been on the rise, reaching €2.4 trillion in 2019, and it continues to grow.

The project, which ran for three and a half years, expanded the availability of bio-based materials for 3D printing by leveraging industrial biotechnology, nanotechnology, and advanced manufacturing techniques. It introduced new processes for extracting and using compounds from agricultural residues, resulting in materials with improved mechanical, thermal, and aesthetic properties.

Though the BARBARA project has concluded, its participants aim to move the technology into the demonstration phase within the next few years, demonstrating its potential for large-scale production. This comes at a crucial time as the global biopolymer industry is growing at a rate of 6% annually, with the European sector expanding by 30% annually.

Another project, ECOXY, focused on finding bio-based alternatives to non-recyclable and toxic plastics known as “fibre-reinforced thermoset composites.” By utilizing lignin derived from wood and plant fibers, ECOXY developed bio-based resins and flax fibers as a reinforcement, creating sustainable materials with properties comparable to fossil fuel-derived counterparts.

These initiatives not only benefit workers’ health during manufacturing but also contribute to long-term environmental sustainability by reducing waste and carbon emissions. They highlight the EU’s commitment to embracing a circular economy, where waste is considered a valuable resource, and bio-based materials play a vital role in reducing the environmental footprint of industries.

Read the full magazine article here.