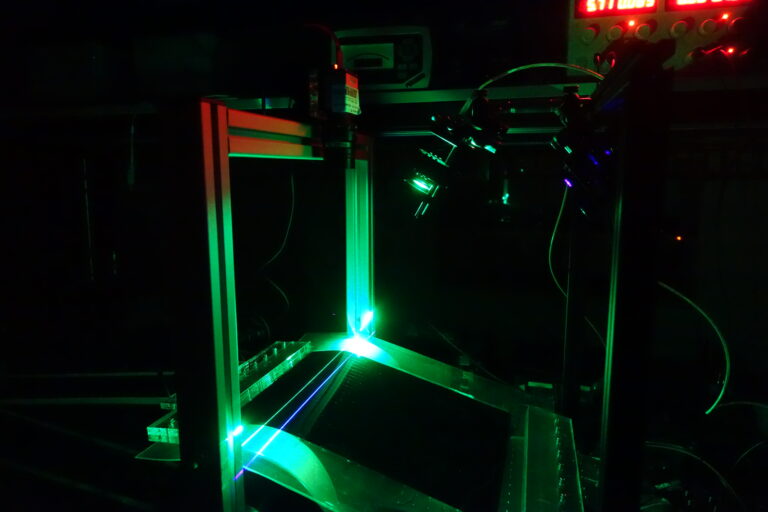

The optical inspection system makes use of artificial intelligence and optical metrology for real-time detection, classification, and visualization of surface defects, artifacts, and texture changes across various morphologies. Based on typical process conditions, the AI precisely identifies even highly complex defects that conventional image analysis tools cannot reliably detect.

Key Features:

- Real-time Analysis: Integrated AI tools and multimodal imaging enable in-line detection and classification of even highly complex surface defects.

- Three-dimensional Measurement: Rapid and high-resolution 3D surface measurements provide additional insights directly during ongoing production.

- Detailed Defect Analysis: Customers benefit from comprehensive information on defect types, defect densities, geometric dimensions, defect frequencies, and many other parameters.

- Modular and Flexible Design: The system’s modular structure allows for flexible adaptation to various applications, such as in the semiconductor industry or the production of fiber-reinforced plastics.

Advantages:

- Increased Production Accuracy and Efficiency: Precise defect analysis and real-time data significantly enhance production processes.

- Versatile Applications: The system’s flexible adaptability makes it suitable for a wide range of industrial applications.