Our state-of-the-art facilities enable the melting of metals and alloys under ultra-pure conditions, achieving exceptionally high solidification rates in the casting process. Additionally, our advanced systems are designed to handle reactive and high-temperature alloys with outstanding precision—withstanding temperatures of up to 2,200°C. Precision engineering for superior material quality!

Add to favorites:

Share:

Listing Description

Offer Details

Specifications and Deliverables:

- Cold crucible casting

- special device manufactured in-house ; development of IFW-Research Technology Department

- Contact-free inductive melting under protective gas or vacuum – no crucible

- Also suitable for reactive metals

- Casting in copper mold (rod diameter: 10 to 12 mm, length ca. 10 cm)

- Subsequent addition of further constituents to alloy feasible

- Arc melting / Suction casting

- Manuf.: Co. E. Buehler

- Melting process via electric arc in small water-cooled copper slots (ca. 10 g) under argon atmosphere

- Also suitable for reactive metals

- Subsequent suction casting in copper molds with small diameters or small rectangular cross section (e.g. rod diameter: 1.5 to 6 mm, rod length: 7 cm) to ensure high cooling rates

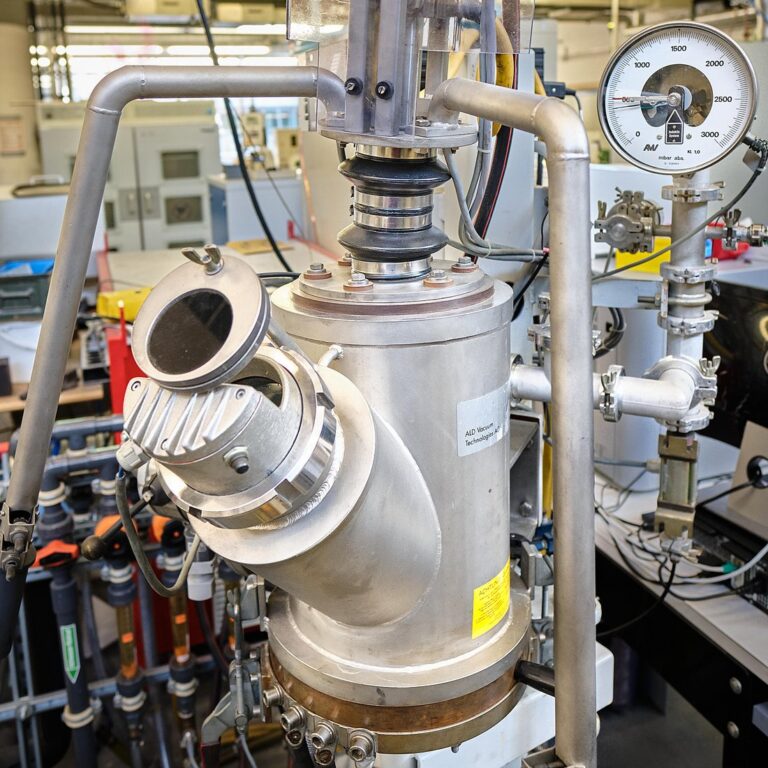

- Arc melting (large)

- Manuf.: Co. ALD

- Melting process via electric arc in water cooled copper sheets (ca. 50 g) under argon atmosphere

- Also suitable for reactive metals

- Centrifugal casting

- Manuf.: Co. Linn High Therm

- For smaller melt volumes (ca. 2 cubic centimeters)

- Melt process under protective gas or vacuum

- Excellent capability for mold filling and high cooling rates effective during centrifugal coating in a copper mold with small diameter (1.5 to 6 mm)

- Eventual turbulences in melt can lead to „marbling“

- Strip casting / Melt spinning

- Manuf.: Co. E. Buehler

- Inductive melting in e.g. SiO2 -and graphite crucibles under protection gas or vacuum

- Also suitable for reactive metals

- Casting on copper wheel

- High cooling rates up to 106 K/s

- Attainable Ribbon thickness: 15 to ca. 50 µm

- Induction casting

- Manuf.: Co. Balzers

- For larger melt volumes (ca. 100 cubic centimeters)

- Melt process under protection gas or vacuum

- Casting in molds of different material (copper, steel…) and different forms (cylinder, cuboid…)

Value Proposition:

- empowering innovation with custom alloy solutions: Design your own alloy for superior performance beyond current standards, prototype your ideas with confidence, and seamlessly integrate our plates, rods, or powder into your processes.

Input Required from Customer:

Fields of Application:

Patent/Publication Number

Main Patent Claims:

Patent Family:

Video

Documents

No documents available.

Location and Map

Sorry, no records were found. Please adjust your search criteria and try again.

Sorry, unable to load the Maps API.

Adress:

Dresden

Saxony

01069

Germany

Contact the listings owner

Connect with the Listing Owner!

💬 Please log in now to send a direct message to the listing owner. Not a member yet? Sign up for free and start connecting today!

Related Funding and Finance Opportunities

Unlock Exclusive Funding Opportunities!

🔑 Get instant access to tailored funding opportunities that perfectly match your needs. This powerful feature is exclusively available to our premium members—helping you save time, stay ahead of the competition, and secure the right funding faster.

Upgrade to Premium now and never miss an important opportunity again! Already a premium member? Log in here to explore your matches.

Related Offers

Unlock Related Offers!

🚀 Gain access to related technology solutions that match your specific needs and interests—carefully selected to support your innovation goals. These offers are exclusively available to our premium members, helping you identify relevant technologies faster and start the right conversations with potential partners.

Upgrade to Premium now and never miss an important opportunity again! Already a premium member? Log in here to explore your matches.

Related Knowledgeable Resources

Discover More with Premium: Related Knowledge Resources

🔒 You’re missing out on expert-curated knowledge specifically matched to this topic. As a Premium member, you gain exclusive access to in-depth articles, guides, and insights that help you make smarter decisions, faster.

Whether you’re preparing a funding proposal, researching a new market, or just need reliable information—our Premium knowledge matches save you hours of research and point you directly to what matters.

Upgrade to Premium now and instantly unlock relevant knowledge tailored to your needs! Already a member? Log in here to view your personalized content.

Viewers

See Who’s Interested in Your Offers!

🎯 Curious about who’s viewing your listings? Unlock insights into your last 20 visitors and discover potential leads instantly! This exclusive feature is only available to our premium members—helping you track engagement, connect with the right audience, and maximize your opportunities.

Upgrade to Premium now to gain access! Already a member? Log in here.

Viewers

See Who’s Interested in Your Offers!

🎯 Curious about who’s viewing your listings? Unlock insights into your last 20 visitors and discover potential leads instantly! This exclusive feature is only available to our premium members—helping you track engagement, connect with the right audience, and maximize your opportunities.

Upgrade to Premium now to gain access! Already a member? Log in here.