The development towards more sustainable solutions for plastic and paper surfaces and membranes is supported by ESNA. ESNA has the expertise on how to design recyclable mono-material based materials, for packaging for instance, depending on the final product requirements, and this expertise is available for the industry. As an example, innovative packaging materials can be designed to be completely recyclable. This can be achieved by using just one major basic polyolefin polymer type while maintaining functionality (e.g. adequate food-protection and prevention of food waste) with approved positive packaging tests for damage resistance, sealability, machinability, gas, and water vapor barrier, and adequate shelf life analysis with selected targeted food types. Consumer request Key Performance Indicators (KPIs) can also be tested at standard level including checks of print quality, package gloss, thickness, modulus, and sealability.

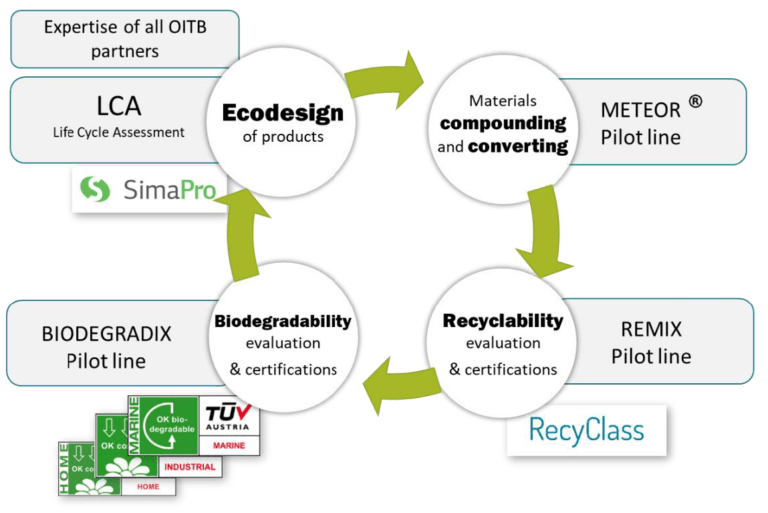

The “Circularity by design” approach combines Life Cycle Assessment (LCA), for an eco-design of innovative products, to the manufacturing processes, such as compounding, along with the recyclability and/or biodegradability evaluations.

The LCA results are used to drive the development toward more sustainable formulations (e.g. for plastic-based products), processes, and End-Of-Life scenarios, and to quantify the potential benefits of sustainable plastic products compared to traditional products.

Such a combinative approach will drastically reduce the needed time-to-market for developing environmentally harmless new plastic products.

The following services are offered:

- The “Circularity by design” service, with a specific methodology for cradle-to-cradle and cradle-to-gate Life Cycle Assessment (LCA) and Life Cycle Cost (LCC) analysis, evaluating the different technological solutions, in relationship with the other Pilot Lines of the OITB;

- Pilot lines such as METEOR® (IPC), high shear rate mixing line (FhG-IVV), slot-die coating (FhG-IVV), thin inorganic barrier coating (AMCOR, FhG-FEP), co-extrusion (FhG-IVV) lines for the development of new formulations, and the production of new sustainable structures, for instance fulfilling the design for recyclability guidelines or bio-based and/or biodegradable;

- A pilot line, REMIX at IPC, for testing the recyclability of flexible plastic products, from the sorting stage down to the use of the recycled materials to manufacture new products, aiming for the official accreditation of Plastic Recyclers Europe – Recyclass;

- A pilot line, BIODEGRADIX at IPC, dedicated to testing the “industrial” and “home” compostability and marine degradability of plastic products, aiming for the official accreditation of TÜV Austria.