Result description

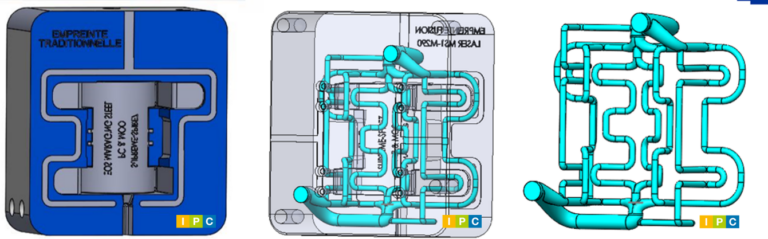

The tooling sector started to be converted to additive manufacturing (AM) to solve the increasing complexity and cost of advanced geometries. AM is popular in tooling for injection molding due to the possibility of providing cooling to the mold insert. For Metal AM processes, available steel grades in laser powder bed fusion is currently limited and do not satisfy highly demanding applications. Maraging steel remains the standard for this application despite several drawbacks. It contains Cobalt which oxides are cytotoxic. It is not stainless and thus corrosion occurs in water cooling channels mold. IPC has developed a process to 3D-print new stainless steel for advanced tooling application. These new 3D printing metal powder will give you access to oxidation-free inserts with structure lattices allowing a lower cooling time of the mold and thus shorter injection molding cycles. The non-toxicity of the cobalt-free alloy will permit a safer use of the powder.

IPC has developed a process to 3D-print new stainless steel for advanced tooling application. This stainless steel has several advantages compare to Maraging steel: its ductility after heat treatment is 5 time higher than the Maraging steel, it is cobalt-free and its corrosion resistance is much higher.

These new 3D printing metal powder will give you access to oxidation-free inserts with structure lattices allowing a lower cooling time of the mold and thus shorter injection molding cycles. The performances of the moldings cycle will be maintained due to the non-oxidation of the stainless mold. The non-toxicity of the cobalt-free alloy will permit a broader and safer use of the powder in the industry. And the energy consumption is reduced at manufacturing thank to the lattice architecture which in turns allows a productivity increase by providing a better temperature regulation.

Addressing target audiences and expressing needs

- Business partners – SMEs, Entrepreneurs, Large Corporations

- Expanding to more markets /finding new customers

We are targeting two market segments in the tooling suppliers and moulding industries. The first segment consists of those who are equipped with additive manufacturing (AM) capabilities and are looking for enhanced sets of parameters for the production of moulds with conformal cooling. They will benefit for the results of our research. The second segment consists of tooling suppliers and moulding industries who are not equipped with AM but are looking for novel conformal cooling moulds. They will benefit of our research and experience as well as our additive manufacturing capabilities

- Other Actors who can help us fulfil our market potential

R&D, Technology and Innovation aspects

TRL: 7-8. The system is complete and qualified in a pre-serial environment, to be extended in mass production trial for lifespan assessment.

CRL:2: First commercial trial is being proposed

IRL: 1 A first business model canvas is in preparation following commercial trial

Result submitted to Horizon Results Platform by CENTRE TECHNIQUE INDUSTRIEL DE LA PLASTURGIE ET DES COMPOSITES