Result description

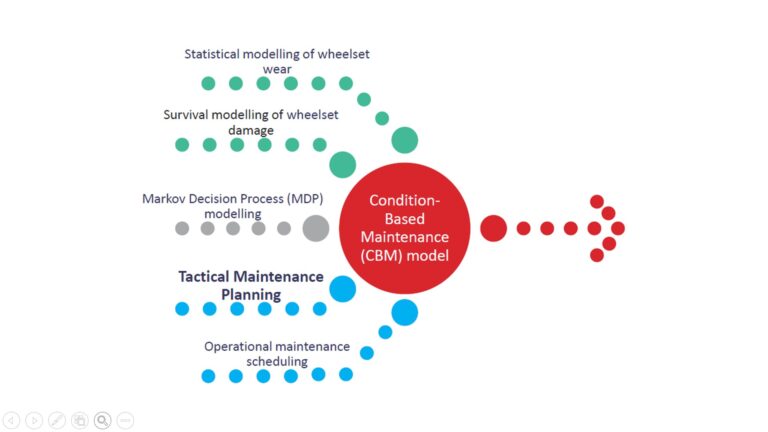

A range of techniques have been combined to develop a condition-based maintenance (CBM) model for railway wheelsets. This model supports maintenance decisions and optimisation of wheelset maintenance activities and has been demonstrated to provide a business and financial benefit.

The CBM model includes Statistical and Survival Modelling of wheelset degradation and Markov Decision Process (MDP) modelling to derive an optimal maintenance decision map. This decision map is then used to trigger maintenance decisions. Decision support models, such as a Tactical Maintenance Planning and an Operational Maintenance Scheduling, have been developed to assess the optimal maintenance strategy. These models have been applied to an industrial case study and were shown to provide a robust method for deriving a CBM strategy map for wheelset re-profiling and, when linked with the maintenance planning models, can integrate the complexity of maintenance planning (including operational and technical constraint in a medium-term horizon). Based on this case study; an impact assessment of condition-based wheelset maintenance activities, operationalised by relaxing the wheelset turning interval, indicated a business and financial case can be made for such CBM interventions. Cost reductions of up to 35% on preventive and corrective wheelset maintenance over the wheelset’s lifetime can be achieved. Up to 3% of total preventive maintenance costs annually can be saved.

Addressing target audiences and expressing needs

- Grants and Subsidies

- Help in technical expertise

- Collaboration

- Public or private funding institutions

- International Organisations (ex. OECD, FAO, UN, etc.)

- Research and Technology Organisations

- Academia/ Universities

Result submitted to Horizon Results Platform by FERTAGUS TRAVESSIA DO TEJO TRANSPORTES SA