Result description

The development of dense fluids required for unconventional pumped hydro by means of using fine coal waste from three case studies was analysed: a dense fluid with a density up to three, in order to achieve a yield up to three times that of the conventional pumped hydro.

Results:

- a) A small surfactant (less than 1%) should be added to prevent the slurry from coalescing and improve flow.

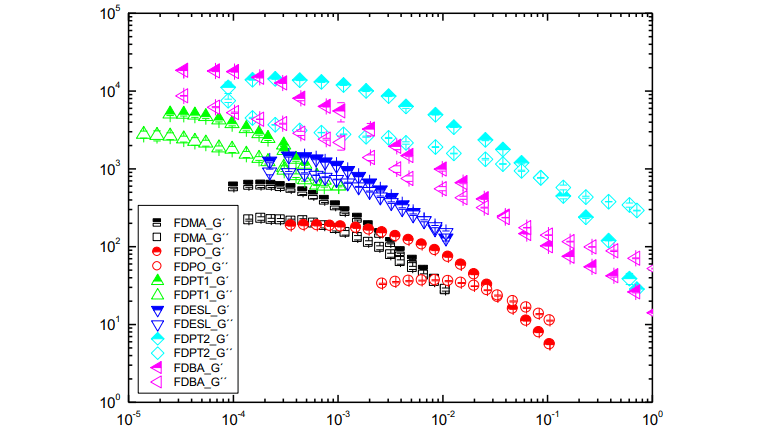

- b) In all cases, in the viscous response and in the range of shear rates that were accessible, it was observed that viscosity decreases with increasing shear rate.

- d) The dumpsite minerals from the mines are initially attractive as base materials for dense fluids. Two of the samples showed values in the interval bounded by our contrast formulations, which have already been used to prepare dense fluids.

Addressing target audiences and expressing needs

- Business partners – SMEs, Entrepreneurs, Large Corporations

- Incubators / Accelerators

- Venture Capital

We need to undergo a pilot using this technology

- Public or private funding institutions

- Other Actors who can help us fulfil our market potential

- Private Investors

R&D, Technology and Innovation aspects

Demonstration of the technology to reach TRL 7

The dumpsite minerals from the mines are initially attractive as base materials for dense fluids.

This technology adds value to energy storage via pumping hydro, multiplying the yield by three, aproximately.

- Global

Result submitted to Horizon Results Platform by MAGELLAN & BARENTS SL