Result description

What it is: A method & material platform creating conductive hybrid materials utilizing lignin (a pulp/paper industry byproduct) and conductive fillers (e.g. MWCNTs).

What it does: Produces sustainable, lower-cost conductive hybrid materials (2-5 S/cm).

Why it’s special: Cost-efficient alternative to pure carbon nanomaterials by significantly reducing MWCNT content to 10-20% wt.

Target: researchers, green-chemistry SMEs, ink formulators, biopolymer producers.

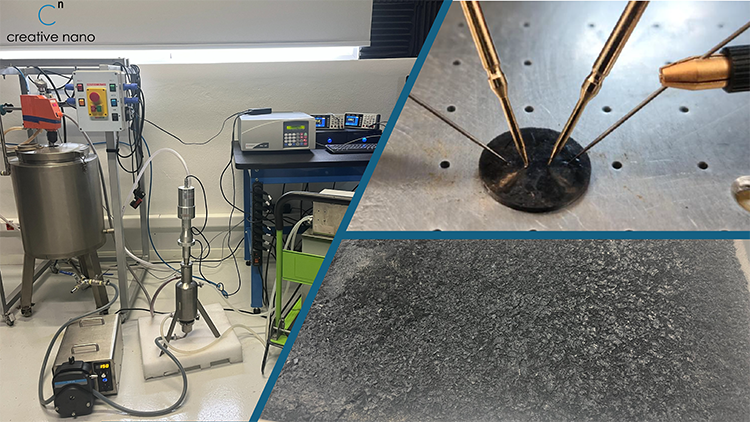

Creative Nano has developed conductive lignin-based hybrids that offer a green and cost-efficient alternative to conventional carbon-based conductive materials (e.g. MWCNTs). By optimising the lignin–based hybrids, adequate electrical performance is achieved while significantly reducing the required amount of carbon nanomaterials through the use of lignin (abudant bioproduct from pulp and paper industry). The water-based, SSbD-compliant process enables scalable production. These materials show strong potential as fillers in eco-friendly conductive inks and coatings, as functional additives in biopolymer composites, and in electrochemical or sensor applications for low-power, flexible, and disposable electronics. The material lowers polymer footprint and valorises industrial lignin streams. IP approach: know-how and patenting strategy under development. Exploitation route: licensing to sustainable ink producers and joint development agreements.

Addressing target audiences and expressing needs

- I/we wish to transfer my/our IPR to an interested party

- Use of research Infrastructure

- Collaboration

Collaboration with formulation partners, pilot trials with converters.

- Other Actors who can help us fulfil our market potential

- Research and Technology Organisations

- Private Investors

R&D, Technology and Innovation aspects

Creative Nano’s conductive lignin–based hybrid materials have been successfully developed and validated at laboratory and pilot scale, achieving stable electrical performance (2–5 S/cm). Next steps include formulation refinement for specific applications (inks, coatings, biopolymer composites), extended performance testing, demonstrator integration, and industrial-scale upscaling.

Lignin–based conductive hybrids are highly scalable thanks to a flexible, water-based, SSbD-compliant process using an ultrasound-assisted pilot line. The production method is engineered for seamless pilot-to-industrial scale-up, enabling increased output with minimal additional resources while maintaining high quality and reproducibility.

The lignin-based conductive hybrids are replicable thanks to established, water-based, SSbD-compliant process. Documented protocols and fractionation SOPs ensure consistent conductivity, structure, and quality across batches, enabling reliable production in contract manufacturing

It valorises industrial lignin streams and reduces reliance on carbon nanomaterials. The water-based, SSbD-compliant process enables safe, scalable production.; end-of-life needs assessment is ongoing.

- Europe

Result submitted to Horizon Results Platform by CREATIVE NANO PC