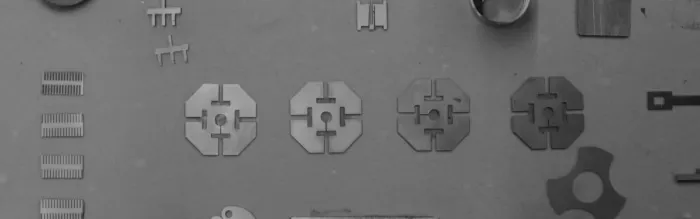

Maximum dimensional accuracy, complex contours and fine surfaces – precise EDM machining for components where conventional machining reaches its limits.

IFW Dresden offers high-precision wire EDM and die-sinking EDM for machining electrically conductive materials. Using state-of-the-art Agie-Charmilles technology, we create complex contours, fine cutouts, and precise fits – regardless of the material’s hardness. Our wire EDM process enables conical cutting up to 45° and machining with an integrated rotary axis, while die-sinking EDM creates the finest contours and undercuts. Ideal for tools, prototypes, functional components, and small series production with the highest quality standards.

Your benefits

- Precise contour accuracy even with complex geometries

- Material-independent hardening

- Finest spark gap sizes for delicate details

- Machining of conical shapes up to 45°

- Use of state-of-the-art Agie-Charmilles systems

Methods & Equipment

- Wire EDM – Agie Charmilles FI 440 ccS

- Working area: 550 × 350 × 400 mm

- Conical cutting up to 45°

- Cutting width: approx. 0.3 mm (depending on material)

- Built-in rotation axis

- EDM sinking – Agie Charmilles Roboform 350

- Working area: 600 × 500 × 300 mm

- Spark gap size: 20 µm – 2 mm

- Gate countersinking up to 45°

Fields of application

- Tool and mold making

- Manufacturing high-precision prototypes

- Machining hardened steels or difficult-to-machine alloys

- Contour-accurate components with delicate details and tight tolerances