Result description

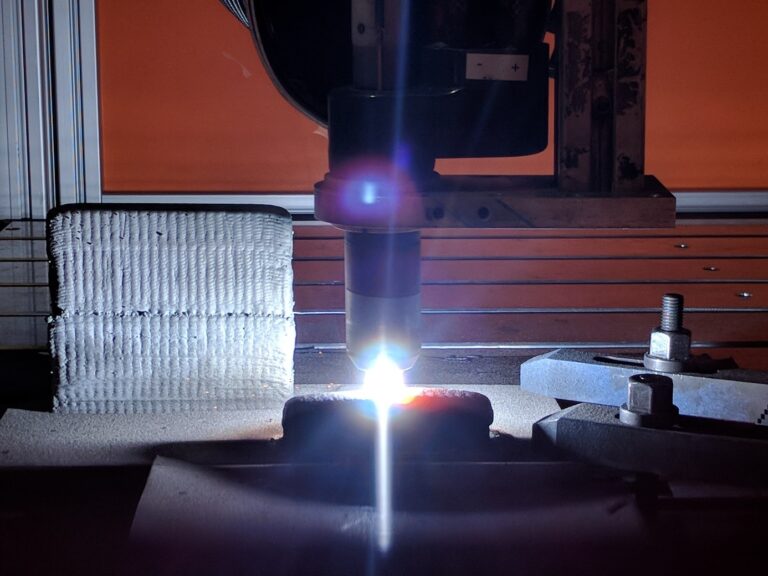

For efficient processing of DED manufactured parts RHP is using a high deposition rate process with more than 2.5 kg/hr for metals suitable for parts of a size of larger 0,5 meter. RHP is able to process various metals such as Fe, Ni, Ti or Al based Alloys.

Addressing target audiences and expressing needs

- Expanding to more markets /finding new customers

New customers from industry and new markets in order to demonstrate the capability of the technology for industrial products

- Other Actors who can help us fulfil our market potential

R&D, Technology and Innovation aspects

High deposition rate systems are implemented in RHP’s equipment, further developments regarding deposition rates, reduction of consumables or better yield in raw material are under continuous development

RHP runs different machines based on this technology to keep flexibility for customers. Raw materials may be water atomised powder, gas atomised powders or wire to keep independency from raw material providers. RHP has a strong link to equipment manufacturer and is developing own equipment components.

Based on customer need RHP is able to document the process ( parameters, weld pool camera, … ) to prove a reliable product at any time.

High deposition rate additive manufacturing of large parts is facing the reduction of raw material consumption and consumption of consumables to enhance sustainability.

- Europe

- Global

Result submitted to Horizon Results Platform by RHP TECHNOLOGY GMBH