Result description

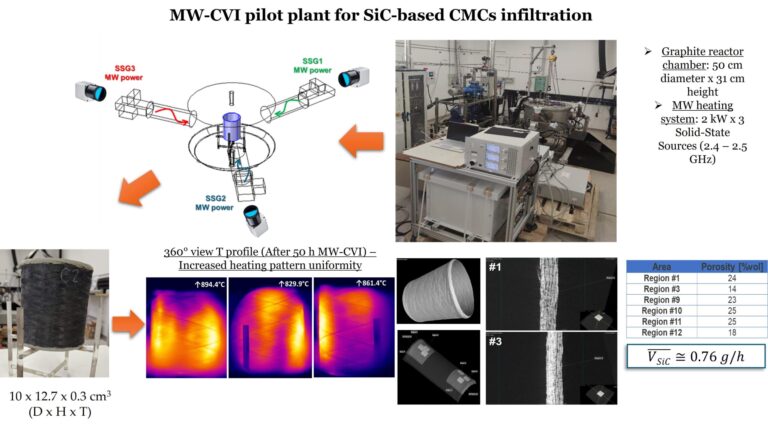

A customized approach enabling the scalability of the Microwave-assisted Chemical Vapor Infiltration (MW-CVI) technology for the production of a SiCf/SiC tube having a diameter of 10 cm, height of 12.7 cm, wall thickness of 0.3 cm, by means of a reactor enabling a multiport and multifrequency excitation around 2.45 GHz, was developed. Comprehensive rigorous numerical modelling of the MW-CVI loaded reactor allowed to reliably identify the optimal frequencies combination, maximizing the process energy efficiency and heating pattern uniformity. A total MW power of 4.5 – 5 kW was distributed among the three available excitation ports, achieving an unprecedented uniformity in the temperature profile of the CMC tube, in the operating temperature range of 800°C – 1000°C. The obtained results pave the way for a wider and more efficient application of MW-assisted processes in high-temperature industrial applications, contributing to the development of alternative greener technologies.

A large SiCf/SiC CMC tube was successfully densified in an innovative MW-CVI pilot plant, overcoming the conventional limitations on the sample dimension, through an efficient combination of overmoded resonant reactor design, multiport excitation scheme, tunable multifrequency excitation, and rigorous numerical modelling of the reactor in the operational configuration. The SiCf/SiC tube relative density increased from 58% to 77% after 50 hours, with an average SiC matrix deposition rate of 0.76 g/h, in good agreement with the reduction of about one order of magnitude of the processing time in comparison to conventional CVI. X-ray micro-CT analyses confirmed the achievement of a controlled densification front, avoiding the crusting issue, and of a homogeneous porosity reduction, further corroborating the potential of this technique for the near-net-shape manufacturing of large tubular SiCf/SiC samples with respect to conventional routes. The results demonstrate, for the first time to our knowledge, that the scalability issue of the MW-assisted processes can be effectively overcome, paving the way to applications at an industrial level and to the full maturity of this technique.

Addressing target audiences and expressing needs

- Grants and Subsidies

- Collaboration

Specialty industries on conventional CVI processing open to share confidentially their process data to further validate this technology to at least a TRL5. Specialty industries open to implement this technology in their production processes. Additional funding to support R&D activities in order to scale-up the technology to industrial productivity targets.

- Public or private funding institutions

- Research and Technology Organisations

- Private Investors

R&D, Technology and Innovation aspects

The production of large-scale SiC-based CMCs by the MW-CVI technology was validated in a laboratory environment in the framework of the EU CEM-WAVE project, thus confirming the achievement of a TRL 4. Next steps should involve the exchange with some of the main industrial players on conventional and variant of the CVI technology to further validate and apply the MW-CVI technology to a higher TRL.

A very high level of reproducibility in the processing of similar SiC-based CMC sample batches was reached thanks to the direct measurement of the main physical parameters of these materials and to a rigorous numerical modelling of the microwave-assisted process evolution. A further key element in the full control of the process is the use of frequency tunable microwave solid-state sources, enabling the setup of the optimal frequency and power according to numerical results. Moreover, the stable and reproducible microwave emission of the solid-state sources allows for the automation of the whole process, as mandatory for industrial applications.

Result submitted to Horizon Results Platform by CONSIGLIO NAZIONALE DELLE RICERCHE