Result description

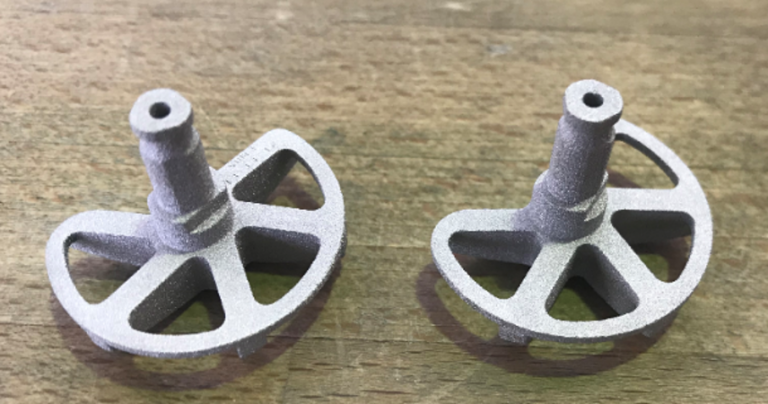

The Glenoid Reamer use-case for Metal Binder Jetting process was manufactured on a HP system. Mechanical properties with as sintered and heat treated status were analyzed. Dimensional accuracy and KPIs regarding energy and material consumption were measured. Predefined requirements provided by end user could be fulfilled.

Addressing target audiences and expressing needs

- Expanding to more markets /finding new customers

Customers with industrial profile (specifically medical market) in the phase to ramp up their parts to small series production.

- Other Actors who can help us fulfil our market potential

R&D, Technology and Innovation aspects

In SUPREME the following goals could be achieved:

- 91% reduction in CO2 emissions by using MBJ compared to machining for medical tool fabrication.

- 91% reduction in energy consumption by using MBJ compared to machining for medical tool fabrication

- 64% reduction in material usage by using MBJ compared to machining for medical tool fabrication

Result submitted to Horizon Results Platform by GKN SINTER METALS ENGINEERING GMBH