With an AMAREA multi-material 3D printer based on the Multi Material Jetting (MMJ) technology you can produce parts and components by combining different materials of the same class of materials, such as metals, ceramics, and plastics and even combine different classes of materials – all in a single build job.

Combine materials to combine material properties for more functionality in structural parts and components.

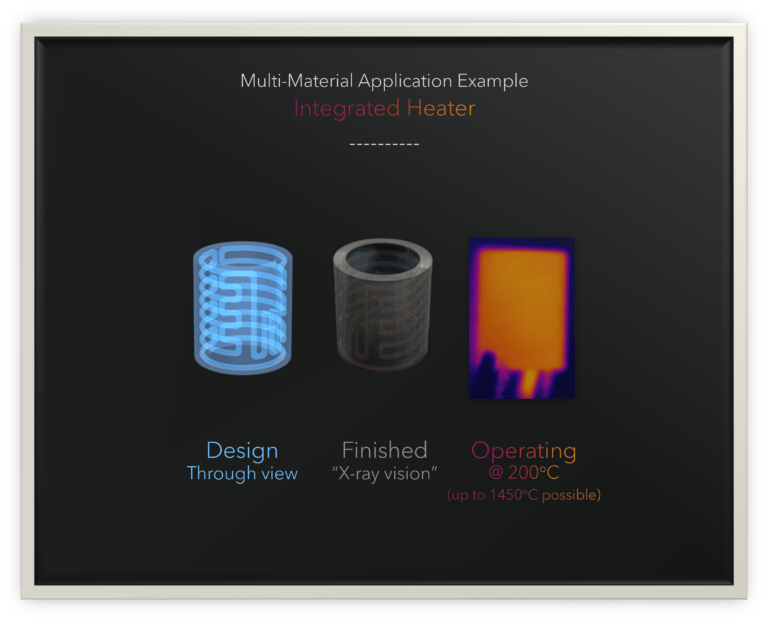

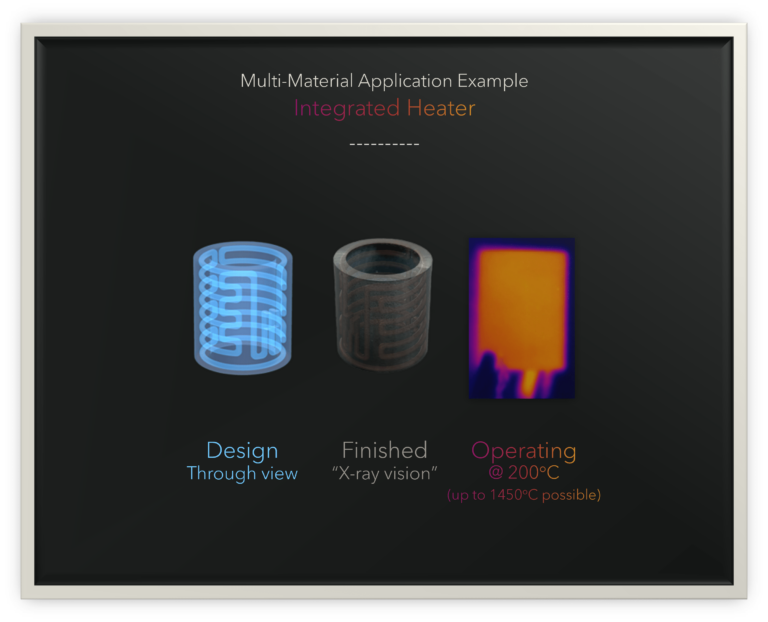

For example. to produce a heated shaping tool, instead of manufacturing separate parts and assembling them, just integrate a heater directly into a shaping tool at the spot where the heat is needed for an effective and efficient process.

Process chain:

The overall process chain is a sintering process chain based on powder technology, i.e. parts from the 3D printer are so-called green parts. Green parts are thermally processed after 3D printing, i.e. debinded and sintered.

AMAREA Multi-material 3D printers:

Modular & upgradable 3D printing system with tailored control software

| Up to 6 print heads: | Combine up to 6 different materials drop-by-drop and layer by layer at high-precision throughout the build volume |

| Integrated 3D profile sensor: | For automated in-line monitoring, build job documentation, and accelerated parameterization |

| Optional laser module: | For in-line green processing, such as ablation, structuring, and smoothing |

| Building envelope (x | y | z): | up to 530 mm x 300 mm x 200 mm |

| Lateral resolution (xy): | from 200 µm for build material from 100 µm for support material |

| Layer thickness (z): | from 100 µm for build material from 100 µm for support material |

| Design file format: | .3mf (open source) |

Printable materials portfolio:

- Oxide, nitride & carbide ceramics

- Alumina

- Zirconia

- Aluminum nitride

- Silicon nitride

- Silicon carbide

- Silicon carbide – Glass

- Titanium oxide

- Hard metals & cermets

- Tungsten carbide cobalt

- Titanium carbonitride

- Sintered glasses

- Borosilicate glass

- Metals & precious metals

- 316L

- 17-4PH

- Silver

- Glass-ceramics

- LTCC

- Polymers

- Particle-filled thermoplastics

- Polycaprolacton

- Custom-made for you

Technically, any material powder can be transformed into a 3D-printable material, depending on the powder properties. Hence, materials which are not already in our portfolio can be added swiftly. Just supply the material powder or let us source it for you and we custom-make a 3D-printable material for you.