Result description

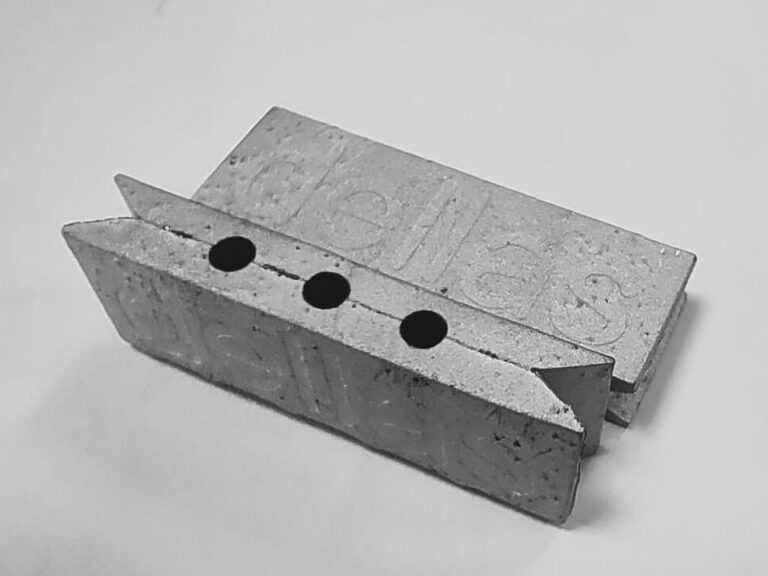

Dellas has substituted the Cobalt matrix from the current Co-diamond composite formulations by a Fe matrix and it has developed the injection moulding process for the production of segments for gang saw to cut rocks, stone and marble.

Addressing target audiences and expressing needs

- Expanding to more markets /finding new customers

New customers and new markets

- Other Actors who can help us fulfil our market potential

R&D, Technology and Innovation aspects

Demonstration at TRL 7 of the global optimization throughout the production route of cutting tools based on FeCuNiP / diamond composite to achieve :

(i) a >25% reduction in material yield losses → -5.3% (Attainement: 53%)

(ii) a >10% improvement in energy efficiency → -35% (Attainement: 100%)

(iii) an increase of 10% in production rate →25% (Attainement: 100%)

(iv) a >30% reduction in CO2 emissions compared to current MIM process →-33% (Attainement: 100%)

SUPREME improvement in the technology represent a distinctive and relevant innovation for DELLAS and generally for European market against Asian competitors. DELLAS is market leader in the field of gang saw (blade) and it is among the first 2 national operators in the diamond tools: the potential market is 20-30% of 30M€ global tool market excluding China market.

If one compares the productivity of the DIM (DELLAS MIM technology) process with conventional Hot press process, there is a clear improvement in the parts manufacturing time, becoming DIM process notably more productive than conventional hot press process: 25% increase in the process productivity.

- Global

Result submitted to Horizon Results Platform by DELLAS SPA