Result description

DiGas has developed NYSMART, a proprietary patented dual-fuel technology tailored for modernization of air-polluting diesel locomotives to promote clean and efficient operations on gas fuels. Once set up, it delivers PM reductions of 95% and lowers NOx and CO2 emissions by 60% and 30% to 40%, respectively. To put this into perspective the conversion of 1 mainline locomotive using renewable gas has the equivalent impact of approx. 350 electric vehicles operating on renewable electricity. Additionally, the use of an advanced intelligent engine management system results in a 30% cut in the fuel costs, delivering a rapid payback for the customer while providing torque and performance matching that of a diesel engine.

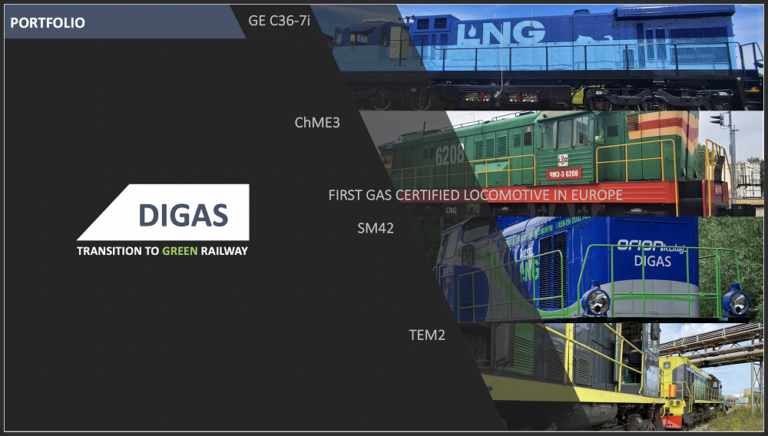

The DiGas NYSMART system was qualified and demonstrated using 4x case study locomotives, and secured full certification from relevant bodies. The outcome of achieving these major objectives is a system that is available and started gaining traction with large rail operators. In doing so, we will deliver the following expected outcomes:

Converted 445 Shunter & 257 mainline locomotives to NYSMART technology by year 2026

Generate Cumulative Revenue & Net Profit, €95.9`million and €16million respectively by 2026

Reduce the amount of diesel fuel used by 84.5 million and 191.1 million litres in the Shunter segment and mainline segments respectively by by the year 2026

Prevent 42.7 million kg CO2 being released to environment and 1.4 million kg NOx by year 2026. Almost complete removal of Sulphur Oxides (SOx) and any other exhaust particulate matter

Reduce lubrication oil usage by 364,100 kg and 819,000 kg for Shunter and Mainline respectively

Addressing target audiences and expressing needs

- Grants and Subsidies

- Business Angels

- Venture Capital

DiGas is currently seeking a Seed Extension funding of 4 million euros for a 24-month period (may be split in stages). The funding is to be used for development and demonstration of fuel cell powered locomotive propulsion system capable to work on Hydrogen and other gaseous fuels. The product will allow railway operators and OEMs to transform the railway fleets to carbon neutral operations.

- Public or private funding institutions

- Private Investors

R&D, Technology and Innovation aspects

NYSMART dual-fuel system is at TRL9 being fully tested and certified. DiGas started the product market roll out with public and private railways. The next steps will ensure a fuel cell propulsion system development and demonstration for locomotives in the next two years.

DiGas system is build based on the principle of modular versatile modules, which are combined for specific application or customer needs. It can be fast and easily applied to virtually any locomotive type, both new and used ones thus creating business potential on the aftermarket and with OEMs. Currently, there are around 100k diesel locomotives in service, which we are targeting in Europe and Americas. Having a product in place for cost effective retrofitting of 4 most widely available locomotive types, DiGas is targeting 30% of the market share already now. Planned development of the hydrogen fuel cell propulsion will create a potential in the remaining market share.

DiGas first has implemented certification approach for alternative fuels powered locomotives approved by EU and international authorities. System components manufacturing is diversified by agreements with alternative suppliers. Development of the system was done with international legislation in mind, technical documentation and business process to allow replicability and localization of the manufacturing in all target markets.

DiGas products are economically feasible for railway operators and manufacturers, resulting in shortest IRR in the industry. Emission reduction of the current product is significant in terms of local and global impact, while development of the new products will lead to carbon neutral railway operations on scale. Additional advantage is that existing locomotives lifecycle will be extended to additional 20-40 years avoiding the excessive costs and raw materials for new units production.

- Europe

- North America

- South America

Result submitted to Horizon Results Platform by SABIEDRIBA AR IEROBEZOTU ATBILDIBU DIGAS