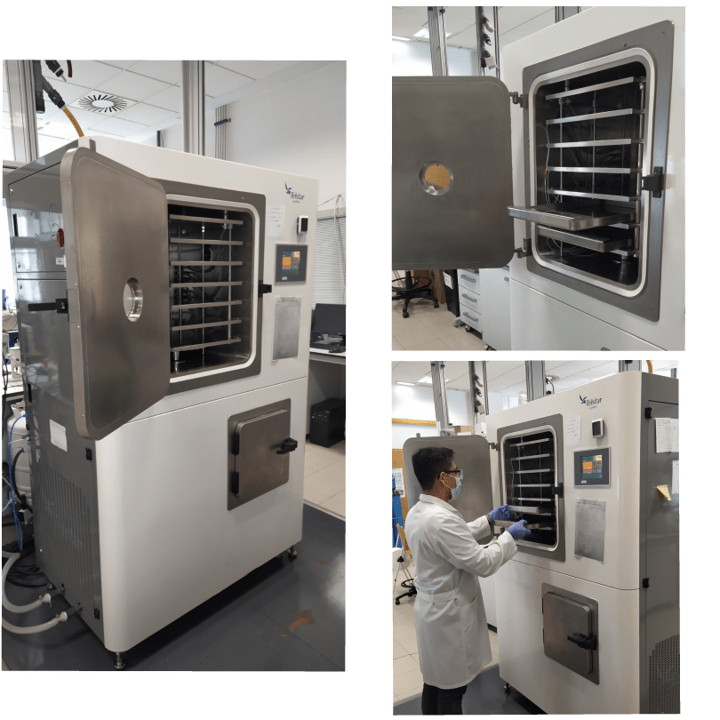

The pilot line consists of a semi-industrial Freeze-Dryer that permits to obtain aerogel panel materials with exceptional properties. The porous material is firstly frozen and consequently sublimated under vacuum by a primary and secondary drying process. The pilot line is a compact unit with casters, constructed in a steel stove-enamelled cabinet. It is equipped with a vial stoppering and spacing device, isolation valve chamber to condenser, micro suite software and a vacuum pump with exhaust filter. The system permits to control the freeze-dryer functions by a Human Machine Interface that offers:

- information about system elements such as: valves, motors, indicator,

- output alarm information,

- modifying the parameters of the freeze-dryer cycle,

- protecting the system from unauthorized use and

- recipe development.

Also, a vacuum sensor is in the chamber to control the pressure of the product environment, enabling the evaluation of the final scale-up results. Monitoring the experimental conditions is possible to fully understand the physicochemical properties of the final product. Additionally, this opportunity allows controlling and improving the energy consumption during the freeze-drying process.