Result description

The Fraunhofer Institute for Ceramic Technologies and Systems IKTS conducts applied research on high-performance ceramics. As a research and technology service provider, the Fraunhofer IKTS develops advanced high-performance ceramic materials, industrial manufacturing processes as well as prototype components and systems in complete production lines up to the pilot-plant scale. In addition, the research portfolio also includes materials diagnostics and testing. The IKTS is certified according to DIN EN ISO 9001, as well as an environmental management system in accordance with DIN EN ISO 14001.

For Thermoelectrics, the IKTS offers setup and interconnection technology, characterisation of materials as also testing of TE-Modules.

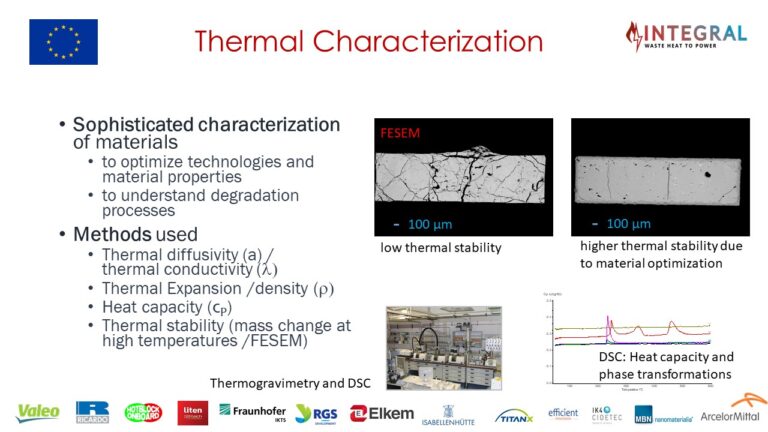

During the project, the IKTS was responsible for offline characterisation at the whole value chain from TE-materials to finally set up TE-Generators. The IKTS got in contact to all applied materials of the three pilot lines: SiGe; MnSi and Half-Heusler alloys as also the different processing types: ribbon casted; spark plasma sintered and melt casted. So for each type individual sample preparing routes as also characterisation procedures have been developed to investigate the applied materials in terms of mechanical strength, thermophysical properties, phase content or microstructure. For characterisation of thermophysical properties the thermoanalytical methods thermogravimetry, differential scanning calorimetry, thermomechanical analysis and laser flash analysis were applied. The focus was to determine material properties (thermal stability, heat capacity, thermal expansion, thermal conductivity and thermal diffusivity) for material and process optimization.

Addressing target audiences and expressing needs

- Collaboration

- Public or private funding institutions

- Research and Technology Organisations

- Academia/ Universities

- Private Investors

R&D, Technology and Innovation aspects

Result submitted to Horizon Results Platform by Fraunhofer IKTS