Many industries are increasingly concerned about the sustainability of their materials. New generation packaging for food or cosmetics and industrial device components are being designed to incorporate recycled plastics. Maintaining the final product’s performance while incorporating recycled materials can be challenging, so a customised characterisation workflow for each product may be the key to success.

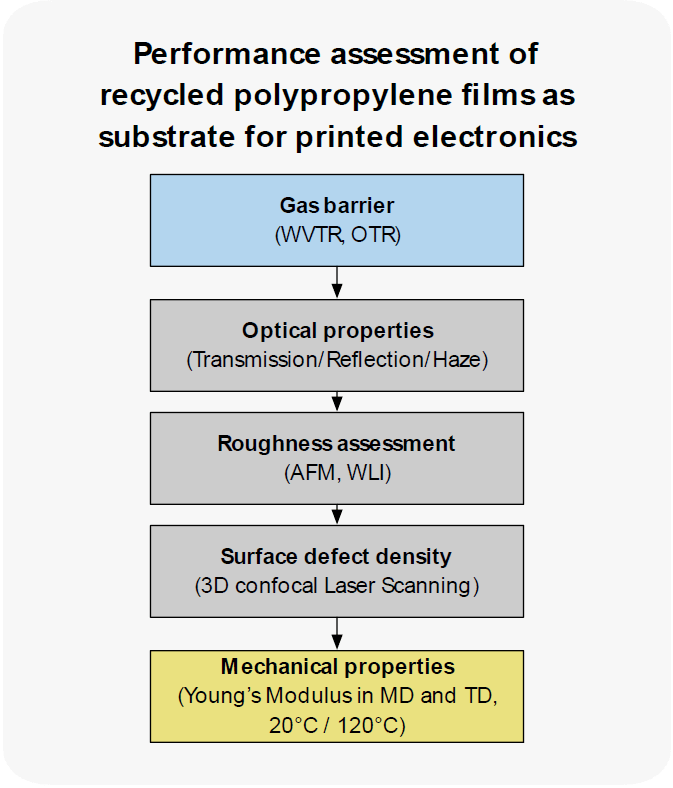

ESNS facilities have testing capabilities to offer performance verification programmes suited to the final applications of each recycled material, combining chemical (e.g., FTIR and RAMAN), thermal (e.g., DSC, TGA, HDT), and mechanical characterisations (e.g., Young’s Modulus) and assessment of gas barrier properties (WVTR, OTR) and failure analysis (e.g., SEM, WLI). The cover image shows an example of the characterisation of recycled polypropylene films intended to be used as a substrate for organic photovoltaic cells (OPV) production. The designed workflow considers multiple steps to evaluate gas permeability, analysis of the presence of surface defects (which could indicate the need to add a planarization layer), and an analysis of optical and mechanical properties to ensure the film’s suitability for the selected application.

Gas and water barrier(WVTR, OTR, Cobb)Paper-packaging performance in applications Mechanical properties(Tensile index, break point, puncture resistance)Food Shelf-life(Microbial growth, chemical analysis, colour)Mechanical properties(Tensile index, break point, puncture resistance; post storage)Surface and crossection characterisation(SEM)Optical properties(Optical spectroscopy)