Result description

Our innovative porous transport electrodes (PTEs), designed using advanced 3D structures, gather a unique set of properties:

- High catalytic surface area

- Efficient gas bubble removal

- Enhanced overall cell efficiency

- No platinum group metals

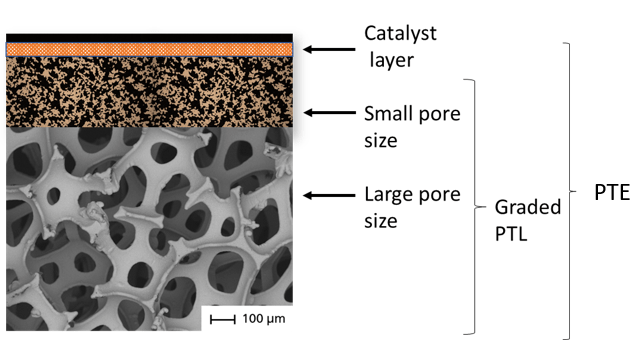

With respect to currently used alkaline electrolysers, our key technological innovation consists in the integration of a 3D structured, laterally graded, flow-engineered, monolithic electrode/PTL concept, which we refer to as PTE = porous transport electrode. This concept features the three following elements:

- 3D structured, laterally graded: In order to optimise bubble removal efficiency during high-rate water electrolysis, it is most helpful to have a laterally graded configuration from the bipolar baseplate towards the membrane or diaphragm

- Flow-engineered: Under upstream electrolyte flow conditions, such graded structures favours bubble removal away from the catalyst into the PTL. As a result, gas bubbles, once formed on the catalyst surface, are directly evacuated, so that the catalyst surface is almost instantaneously refreshed.

- Monolithic PTE: The PTL and catalyst layer are combined into a single doublelayer PTE which improves the manufacturability and stackability of the concept. Additionally, the issue of increased contact resistance between the electrode and PTL, which appears when using physically separated catalyst and PTL layers, disappears.

Addressing target audiences and expressing needs

- Grants and Subsidies

- Collaboration

- Fellowship to advance my/our research

The electrode products are currently developed in a consortium consisting of companies, research centres a university. According to our exploitation plan, two support options would be welcomed:

- Potential investors

- Development partners

- Public or private funding institutions

- Research and Technology Organisations

- Academia/ Universities

R&D, Technology and Innovation aspects

The PTE concept, presently at TRL 3 will be brought to TRL 5 as a result of the ENDURE project: at the end of the project, PTEs will be tested in a 10-kW prototype stack with a cell footprint of ≥1000 square centimeters.

Result submitted to Horizon Results Platform by FRAUNHOFER GESELLSCHAFT ZUR FORDERUNG DER ANGEWANDTEN FORSCHUNG EV