Result description

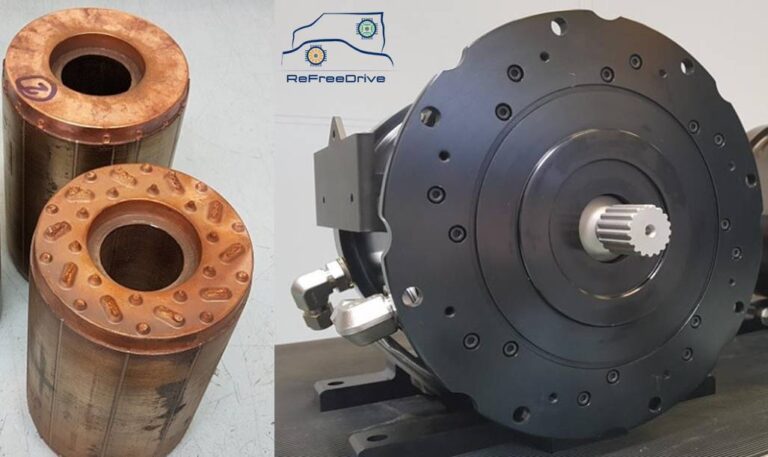

Performance: the Induction Motor prototypes developed are based on inner rotor topology in combination with high rotational speed (up to 20.000 rpm) to increase torque density and specific power, maintaining peak efficiency above 95%. Two operation modes will be explored via control algorithms: 200 kW and 75 kW.

Scope: compared to existing solutions in the market, the solution developed aims to achieve the following figures: +30% specific torque; -50% direct motor losses; +50% power density in power electronics; and -15% production costs in mass production.

Addressing target audiences and expressing needs

- Grants and Subsidies

- Expanding to more markets /finding new customers

- Further grants or subsidies to continue the development of the permanent magnet assisted synchronous reluctance motors

- Research partners that can provide added value to the current developments in next research programmes

- Find customers or industries that can help to fulfil our market potential with regards to this result

- Public or private funding institutions

- Other Actors who can help us fulfil our market potential

- Research and Technology Organisations

- Academia/ Universities

R&D, Technology and Innovation aspects

Current stage: die-cast rotor prototypes manufactured and tested for 75 kW and 200 kW power ranges. Fabricated rotor prototypes manufactured for 75 kW and 200 kW power ranges.

Next steps: further development of the technology and the existing prototypes, or progressing in the commercialization of the current prototypes

Result submitted to Horizon Results Platform by AURUBIS BELGIUM SA