Result description

The benefit of having a wireless integrated Health Monitoring systems on the dry reinforcements adds potential benefits to every step of the lifecycle of the part: from part production: lamination, preforming and curing ( close monitor and in situ evaluation of the correct processing is being followed, ensuring quality of the part is achieved) and during the life of the part the wireless system will aim to facilitate the regular inspection/maintenance of the parts without having to do any extra operation ( such as disassembly and re-assembly). This last part will save time and improve safety. It could also save money by improving the accuracy of the life of the part. Finally, when it comes the end of life of the part, the presence of the microwires will not present any negative impact on the recycling process of the part.

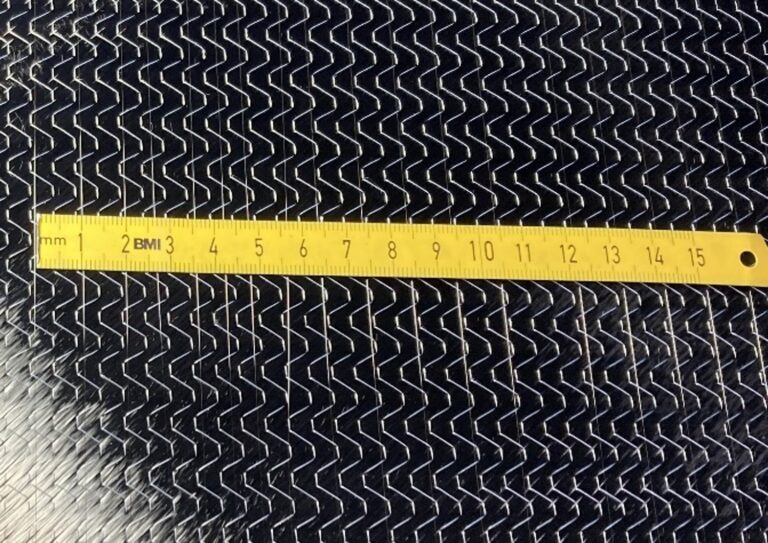

Teijin successfully managed the insertion of the microwires into the Dry Reinforcement (Non-crimp-fabric- picture below).

The major impact of this technology will be on the safety of the part during its working life. The fact that each part could potentially be monitored on a regular basis without having to do any extra operations on the plane ( today an operator will have to check the part itself, with the obvious access limitations ) is a significant achievement. In addition, this system will help to accurately predict the life of the part, which eventually will impact cost/time saving. Part manufactures could also see the impact on less hardware needed to monitore infusion and cure cycle of the part, and reduce /optimised NDTs analyses as part of quality control.

- Grants and Subsidies

Further research in the development of sensors and analyser based on the usage of ferromagnetic microwires to be embedded in composite structural parts, in order to monitor manufacturing and structural health throughout the whole life cycle of the component. The wireless monitoring system will allow producing digital signals and vast sets of data linked with the specimen to create an as-built digital twin of the structure that will also account for the whole history since it was manufactured through all maintenance operations performed.

- Public or private funding institutions

- Research and Technology Organisations

- Academia/ Universities

R&D, Technology and Innovation aspects

Further research is needed

Result submitted to Horizon Results Platform by FUNDACION GAIKER