Result description

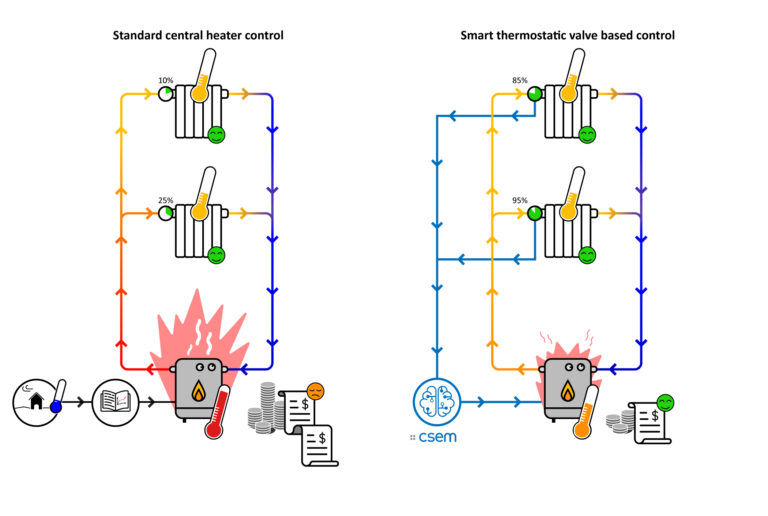

Reduce heating cost by automatically adjusting the heat production by relying on real time data provided by smart thermostatic radiator valves. Commissioning time is drastically reduced as no heating curve tweaking is required. In addition, losses in pinings for instance are reduced and heat generator efficiency increased (as the forward temperature is lowered). At the same time, user comfort is guaranteed as the solution continuously adapts to information provided from the radiators.

First field results were generated in the domOS project on a building located in Neuchâtel (Switzerland). The mixed residential-tertiary building is composed of about 80 radiators that were equipped with smart thermostatic valves from HORA (smartdrive-mx) and MClimate (vicki) as well as the necessary communication infrastructure. The algorithm operated as expected with minimal manual adjustment. The preliminary results have demonstrated an thermal energy saving of 10-15% when compared to the default heating curve (that was adjusted with nigh set-back). This can be tracked back to lower losses in the piping for instance, the forward temperature of the heating fluid is lower on average from 2-5°C when compared to the heating curve (for an equivalent outdoor temperature). Naturally the indoor comfort, is maintained. These results confirm the simulations that were carried out during the THERMOSS project (grant ID: 723562).

Addressing target audiences and expressing needs

- Business partners – SMEs, Entrepreneurs, Large Corporations

- Technology Transfer Expertise

Transfer the technology to a player in the domain of: building automation, smart thermostatic valve or heating solution manufacturing

- Other Actors who can help us fulfil our market potential

- Private Investors

R&D, Technology and Innovation aspects

The concept is under validation in field tests. Current results confirm the findings carried out in simulation.

The control algorithm concept is functional. Efforts are now to be made for integrating the algorithm in an industrial solution.

The overall concept relies on smart thermostatic valves, currently several candidates were tested. However, an ideal valve has not yet been identified (ideally: based on energy harvesting, with a convenient user interface).

The driving principle of the concept is that lower forward temperatures lead to lower losses in piping for instance and better efficiency in heat generators (heat-pumps, gas boilers, …). In addition in most cases these heat generators are configured by standard heat curves with the desire of ensuring user comforts (i.e. in general too warm) and do not take into account the real user needs.

By using smart thermostatic valves, information at radiator level is obtained that allows controlling the heat generator so that heat generator heats at just the right temperature and not a few degrees above to make sure that users have some safety margin. Indeed this safety margin is now not needed as the smart thermostatic valves provide detailed information about user needs in terms of heating requirements.

Energy usage is to be reduced, which is the aim of our approach.

In addition, smart thermostatic valves are becoming increasingly popular.

In consequence, the solution could become a standard long-term solution.

Result submitted to Horizon Results Platform by CSEM CENTRE SUISSE D’ELECTRONIQUE ET DE MICROTECHNIQUE SA – RECHERCHE ET DEVELOPPEMENT