Result description

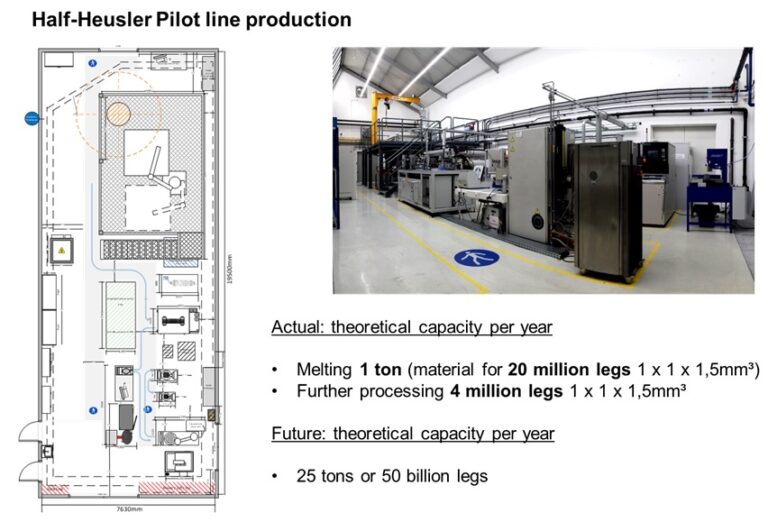

The Ingot size at the end of the upscaling process is about 100 x 100mm² in area and 130mm in high. The weight of such an ingot is about 10 Kg. To reach the 20Kg goal we developed a production of up to four such ingots or 40 kg material per production run. In the WP6 production runs of each 5 times 20kg batches were carried out. This ingots were further processed into the small single leg components. The WP6 production runs were a precious experience and enabled the chance to investigate the pilot line processes under real serial like industrial conditions. This gave the chance to assess each pilot line process. In the end we are able to conclud that the pilot line is able to produce Half-Heusler material in a much lager amount and higher qualitiy than possible in the lab. So we are able to confirm the TRL7 target. To reach the TRL10 and thus the full industrial scale, further work has to carry out.

Addressing target audiences and expressing needs

- Business partners – SMEs, Entrepreneurs, Large Corporations

- Use of research Infrastructure

Potential customers for thermoelectric power generation

- Other Actors who can help us fulfil our market potential

- Research and Technology Organisations

R&D, Technology and Innovation aspects

The objective of Isabellenhütte in this task was to upscale the Half-Heusler TE material fabrication process on the existing Pilot Line from TRL 4 to TRL7, in particular to increase production volume up to 20 kg batches and production yield towards 5% faulty parts.

Result submitted to Horizon Results Platform by ISABELLENHUTTE HEUSLER GMBH & CO KG