Temperature and humidity – two factors influencing atmospheric corrosion – are monitored and controlled routinely in various applications. However, corrosion is drastically accelerated by minor air pollution with nitrogen oxides or sulphur oxides, ammonia, chlorides, organic acids or other volatile substances. Although the concentration of individual significant impurities can be measured today using complex measurement technology, corrosion is a consequence of the complex interaction of many influencing variables.

Especially in the transport industry, in industrial rooms, museums or archives, there is a great need for a simple and reliable measuring technique for monitoring air quality, which is not only limited to temperature and humidity. Today‘s requirements for monitoring air corrosiveness can hardly be met by placing corrosion coupons. Instead, a real-time corrosion analysis with real-time networked data transmission is required.

As part of the European research project „MUSECORR – Protection of cultural heritage by real-time corrosion monitoring“, a consortium of representatives from research, museums and industry has carried out extensive investigations and developed a transportable and easy-to-use real-time corrosion measurement technology to monitor the effects of corrosive gases from the environmental atmosphere using the example of cultural objects.

With their vacuum-based precision coating technologies, the researchers at Fraunhofer FEP have developed a method for depositing thin metal layers precisely and in a reproducible way on exchangeable sensors for indoor applications. The „indoor sensors“ prepared at the Fraunhofer FEP on the basis of very thin metal layers proved – as desired – to be extraordinarily sensitive. Thin layers of different metals react specifically to various air pollutants, so that a broad spectrum of corrosive effects can be detected by combining several metals. The corrosion measurement technology, which was originally tailored for the museum branch, is now also proving extremely useful in industry and environmental protection.

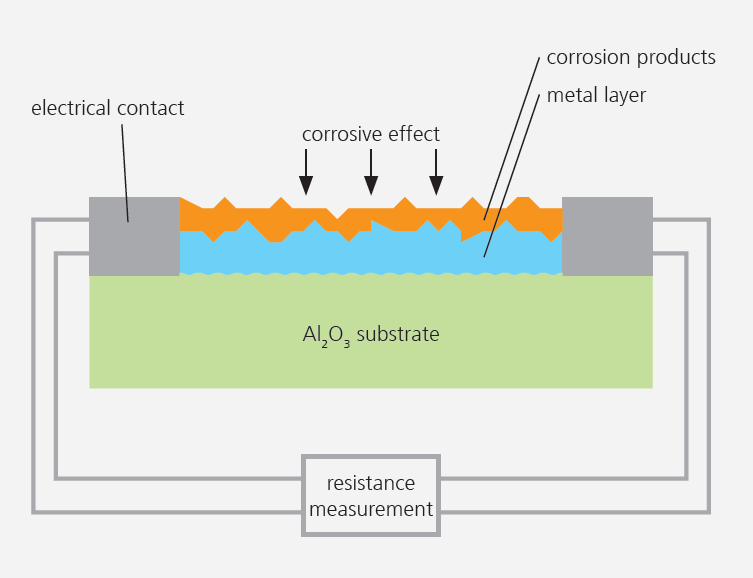

Measuring principle

The sensor consists of a thin metal layer (0.05 – 2 μm) of copper, silver, lead, iron or bronze applied to an insulating ceramic carrier plate. The sensors are equipped with plug-in contacts and can be easily replaced at the end of their lifetime. The change in resistance caused by corrosion of the metal layer is recorded and used as a measure of corrosion progress. The measurement of the electrical resistance of the thin films is extremely precise. Due to the four-terminal sensing technology used, the measurement is free of influences of the supply line and contact resistances. The temperature dependence of the electrical resistance is compensated.

Our service

- Development and provision of corrosion sensors based on thin metal layers

- Development and adaptation of the measuring electronics for recording the electrical resistance and its temporal change

- Customer-specific adaptations with regard to the

- selection of suitable metals and layer thicknesses

- sensitivity and lifetime of the sensors

- measuring ranges of the measuring electronics

- desired data interface port

- operating mode (fixed installation, battery driven, …)

- Software programming on request

- Consulting and market studies

Fields of application

- Transportation, logistics ->Sensitive products such as electronics, musical instruments, artworks

- Chemical industry

- Pulp and paper industry

- Electronics- and semiconductor manufacturing

- Research and Development

- Environmental technology, monitoring of emissions and immissions in indoor environments

- Museums, libraries, archives

Flyer: Thin-film corrosion sensors