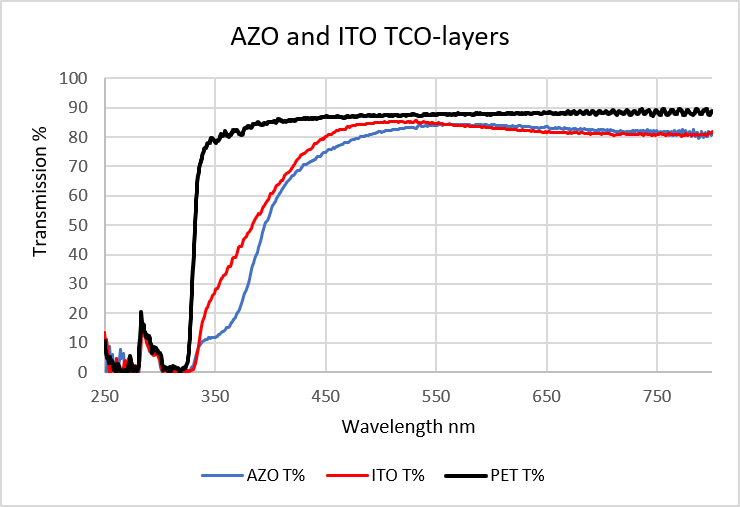

Many applications such as photovoltaics, LEDs, and display elements require an electrode with high conductivity and simultaneously high transmission. The most commonly used material to date is a thin layer of indium tin oxide (ITO). On flexible substrates, the thickness of the ITO layer is limited because its ceramic properties only allow for low flexibility. This means that the lowest possible sheet resistance is approximately 40 ohms/square. With greater thicknesses – and thus lower sheet resistances – the layer will break under flexural stress. In addition to ITO, aluminum-doped zinc oxide (AZO) is also a transparent conductive oxide.

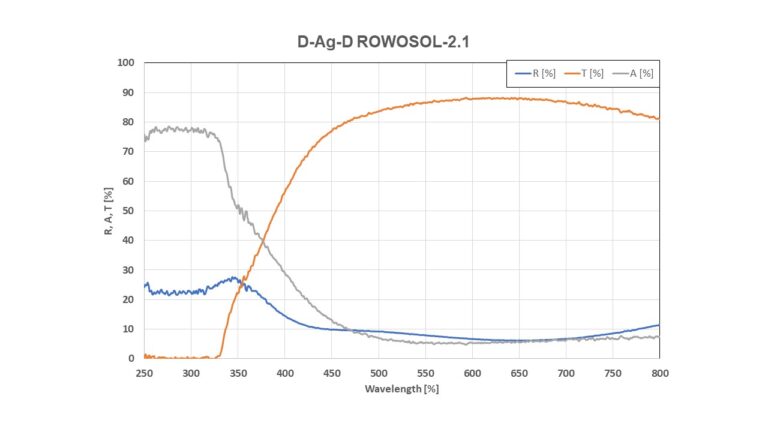

Thin layers of silver have much higher conductivity, allowing for sheet resistances below 10 ohms/square while maintaining high flexibility. However, they also exhibit high reflectance in the visible spectrum and are susceptible to corrosion from environmental influences. When the silver layer is embedded in transparent conductive oxide layers (D-Ag-D or I-M-I), reflection can be significantly reduced due to their anti-reflective properties. By adjusting the refractive index and layer thickness, transmission is noticeably increased. Typical transparent conductive oxides include oxides of tin, niobium, and bismuth, in addition to AZO oxide. This variant of the transparent silver electrode (TSE) was developed in the EU project “TREASORES” (FP7/2007-2013, No. 314068) in cooperation with the Fraunhofer Institute ISE in Freiburg. Based on thin layers of silver embedded between dielectric AZO layers (D-Ag-D), sheet resistances in the range of 6-8 ohms/square were achieved, which are significantly lower than ITO values while maintaining comparable high transmission but lower manufacturing costs.