The FlexFunction2Sustain open innovation test bed offers an open access model for SMEs and industries, providing unique facilities for the nano-functionalization of flexible plastic and paper surfaces and membranes. The project encompasses state-of-the-art equipment across four clusters:

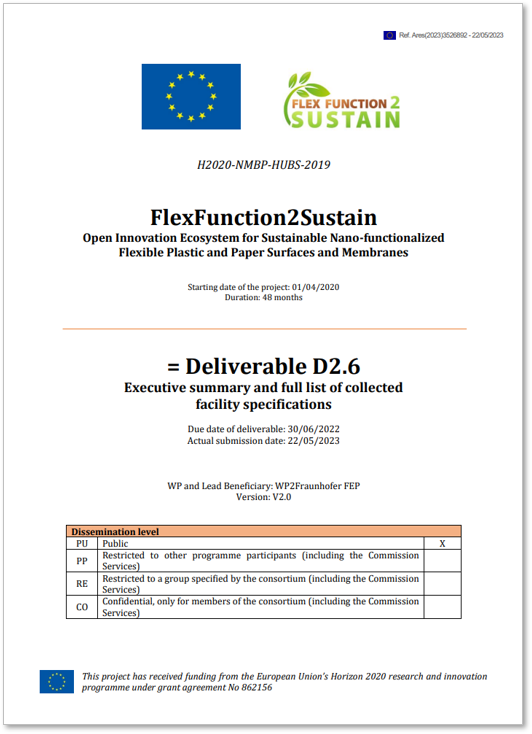

- Vacuum Coating Equipment:

- Machines like the LabFlex® 200 and NovoFlex® 600 enable vacuum roll-to-roll sputtering and coating, capable of processing polymer films, metal foils, and textiles. They specialize in optical coatings, permeation barriers, and coatings for batteries.

- Additional systems like LBnano and the Sheet-to-Sheet Atomic Layer Deposition (ALD) provide nanoparticle aggregation, PECVD, and ALD for substrate sizes up to A4.

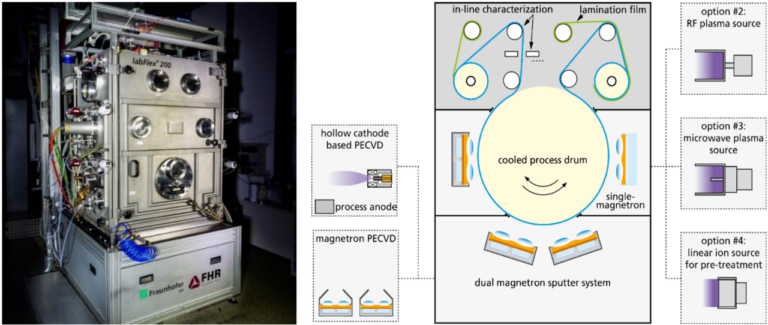

- Atmospheric Pressure Equipment:

- AtmoFlex 1250 offers roll-to-roll coating for polymer films using electron beam curing and slot-die coating.

- The R2R Coating and Lamination machine supports flexible films for food packaging and technical applications.

- Coatema’s Click and Coat® pilot lines (CC08 and LS29) specialize in nanocellulose barrier coating, printed electronics, and sustainable packaging with multiple coating techniques.

- INL’s ultrasonic spray coating machines and BLNano’s nanoparticle deposition systems are tailored for biopolymer coatings and antimicrobial surface applications.

- Nano-Structuring Equipment:

- JOANNEUM RESEARCH’s R2R UV Nanoimprint pilot line specializes in optical films, lab-on-foil, and biomimetic structures.

- AUTH’s Laser Structuring Facility enables laser processing for organic photovoltaics and OLEDs.

- Coatema’s Nano-Imprint-Lithography test facilities offer roll-to-roll lamination for optical security films and recyclable packaging.

- Printed Electronics Equipment:

- AUTH’s Flexible Printed Electronics Line and OVPD machine facilitate printed electronics production for polymer films.

- Fraunhofer IAP’s Sheet-to-Sheet Printed Electronics Line integrates ALD, inkjet printing, and vacuum evaporation for organic electronic devices.

These diverse machines and facilities enable cutting-edge research and development in flexible electronics, sustainable packaging, and advanced coatings, serving as a comprehensive resource for industry innovation.