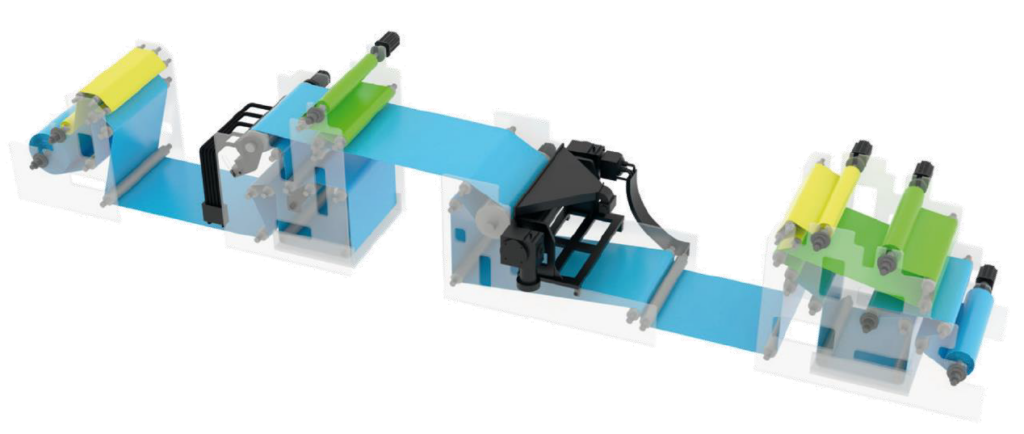

atmoFlex 1250 roll-to-roll machine for coating, laminating, electron beam curing and treatment

ROLL-TO-ROLL PILOT WET COATING LINE

The wet coating of polymer films and other flexible substrates and their modification allows these materials to be used in a wide range of products. Roll-to-roll plants allow coatings to be efficiently applied at favorable cost.

With the new coating line atmoFlex 1250 (manufactured by 3D-Micromac GmbH, Germany) optical and decorative functional layers, abrasion resistant layers and structured layers manufactured by embossing processes can be applied. The maximum web speed of 150 m/min ensures highly productive coating processes. Wet and dry lamination processes are also possible with the atmoFlex 1250.

The wet coating takes place through a 1.2 m wide slot-die, ensure highly uniform 1 1.2 m wide slot-die, heatable up to 50°C 2 atmoFlex 1250, topview 3 atmoFlex 1250, rewinding section with lamination capabilities layers in web and cross-web direction. The crosslinking of lacquers will be done by means of an electron beam system. This system may be used also for post-curing of polymers or sterilization of polymer webs or textiles.

All rollers within the atmoFlex 1250 are optimized regarding diameter and surface to handle pre-coated materials properly. Therefore vacuum coated materials maybe processed without altering the thin and delicate vacuum layers. The atmoFlex 1250 enables Fraunhofer FEP to provide a complete in-house process chain for research and development of multilayer systems, made by wet and vacuum coating processes at industrial scale.

Technology

- slot die

- lamination

- electron beam curing

- electron beam treatment

- in-line pre-treatment/ contact cleaning

- optimized handling of pre vacuum-coated

substrates

Our offer

- development of technologies for coating polymer films and other flexible materials

- coating tests of lacquers, cured by radiation for different applications (optical and decorative functional layers, abrasion resistant layers, permeation barrier layers)

- development and testing of key components

- sample provision for testing and marketing purposes, and pilot production

- studies on the efficiency of coating processes

Deliverables

More Info and Video

Contact Listings Owner Form

- Learn about who has visited this offer

- Get funding opportunities matching this technology

- Get detailed access statistics as listing owner