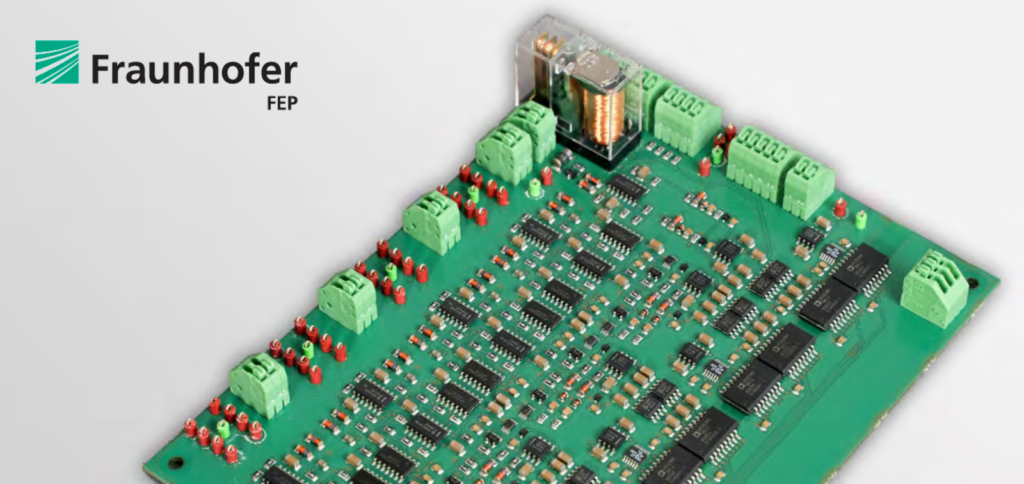

Process-oriented development of control and power electronics for electron beam and plasma sources

Optimized treatments of surfaces and coatings can be achieved when hardware, control electronics and process are optimally matched.

Established control units and power supplies available on the market are often insufficient for demanding, innovative processes. For this reason Fraunhofer FEP has been developing technological core components and processes for many years, which are already in use in many industrial areas.

Fraunhofer FEP has a process-oriented hardware and electronics development department and offers research and development services for customized power supplies and control technology that are optimally adapted to the technological core components. The team of physicists, electrical and process engineers always keeps focus on the overall system and can respond to customer requirements in the best possible way. Depending on the requirements existing technology platforms (see back page) can also be used.

Our offer

- Development and prototyping of custom control hardware and pulsed power supplies, in particular for plasma and electron beam sources including process-specific measurement technology

- Design and manufacturing of customized coils, especially for guiding and shaping the electron beam (static as well as highly dynamic focusing, stigmization, deflection)

- Technical consulting services

- Simulation services (electronic circuit, thermal, electromagnetic field and structural mechanics simulation)

Flyer – For additional Information

Deliverables

– Enhanced performance and reliability of these sources due to improved control systems.

– Process-specific measurement technology that allows for precise data collection and analysis, leading to better process control

– Delivery of customized coils for electron beam applications that meet the desired specifications.

– Improved electron beam quality through static and dynamic focusing, stigmization, and deflection

– Potential cost savings and efficiency improvements in various industrial and scientific applications

– Clients receive expert advice and guidance on their projects related to plasma, electron beams, or other specialized technologies

– Solutions to technical challenges, improved project planning, and potentially increased efficiency in the development of relevant systems

– Knowledge transfer and skill enhancement for client teams

– Accurate simulations and modeling of electronic circuits, thermal behavior, electromagnetic fields, and structural mechanics for various applications

– Identifying and mitigating potential design flaws and issues before physical prototyping or production

– Cost and time savings through reduced iterations and improved designs

More Info and Video

Contact Listings Owner Form

- Learn about who has visited this offer

- Get funding opportunities matching this technology

- Get detailed access statistics as listing owner