Validation of Long term activity of antimicrobial materials

Antimicrobial coatings incorporate chemicals or nano-structured surfaces that kill or inhibit the growth of disease-causing pathogens, preventing or limiting their transmission. In recent years, the demand for antimicrobial coatings has grown exponentially, largely due to, among other factors, the proliferation of multi-drug-resistant bacteria, and the emergence of zoonotic outbreaks such as the recent COVID-19 pandemic. One of the major challenges in the development of such coatings is to ensure persistent antimicrobial effectiveness over time. Despite having a good immediate antimicrobial activity, a coated or nano-structured surface may not offer adequate protection if it degrades and fails before its intended life cycle. This is especially true for materials subjected to frequent stress and washing under harsh conditions (such as coated textiles), constant friction (such as on seating surfaces), frequent wiping with aggressive cleaning solutions (such as on furniture surfaces) or weathering due to exposition to light sources and heat. To ensure the successful development of novel functionalised surfaces, the assessment of antimicrobial performance must be combined with tests to evaluate the integrity of the coatings.

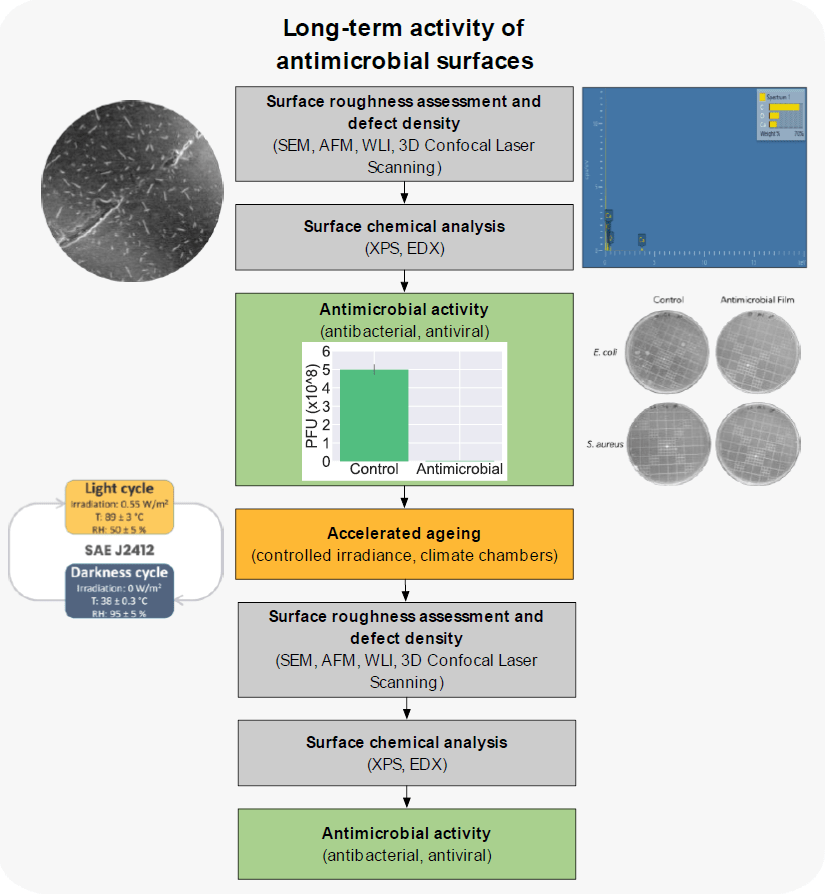

An example of this type of characterisation can be found in the cover image. In this workflow, a plastic material with an antimicrobial coating incorporating metallic nanoparticles is characterised for its long-term antibacterial activity. The physicochemical properties and the nanostructure of the surface are characterised at the beginning of the process using a combination of optical and electron microscopy techniques (e.g., White Light Interferometry, 3D Confocal Laser Scanning, or Scanning Electron Microscopy) and X-ray analysis (e.g., XPS or EDX), and the antimicrobial activity is analysed according to industry standards (e.g., ISO 22196). The materials are then exposed to an accelerated ageing cycle (e.g., SAE J2412). At the end of each ageing cycle, surface properties and antimicrobial activity are re-evaluated.

Contact Listings Owner Form

- Learn about who has visited this offer

- Get funding opportunities matching this technology

- Get detailed access statistics as listing owner