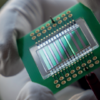

Machine separates old solar modules layer by layer: The result is impressive

A company in Texas has developed an innovative machine to address the growing issue of recycling old solar modules. With an estimated 8 million tonnes of module waste by 2030 and 80 million tonnes by 2050, traditional recycling methods struggle due to the complexity of solar cells' composition. Solarcycle, the Texas-based company, specializes in efficiently separating and recycling various components of solar cells, aiming to minimize the environmental impact of the solar energy industry. Their strategy involves advanced technologies to optimize component separation, resulting in better material recovery and reduced energy consumption. Solarcycle's process costs only about $15 per module, significantly lower than the average of $20 to $40. The company's capacity ranges from 500,000 to one million modules annually. Their process involves removing the aluminium frame, separating the protective glass pane for reuse, and obtaining a granulate containing valuable materials like copper, aluminium, tin, silicon, and silver. Solarcycle collaborates with industry experts to develop efficient and eco-friendly recycling programs, emphasizing the importance of recycling end-of-life solar cells.

Watch the Video

Read the original news article in german here.

Machine separates old solar modules layer by layer: The result is impressive 0 reviews

Login to Write Your ReviewThere are no reviews yet.