Quality control

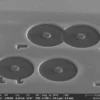

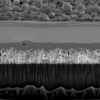

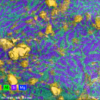

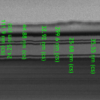

Failure analysis and quality control based on high-resolution electron microscopy and spectroscopy

Modern industry relies more and more heavily on quality control and quality assurance for manufactured parts. These are indispensable elements when faced with growing complexity and ever higher standards of reliability imposed on new products. Failure analysis constitutes a critical aspect of quality oversight (FMEA), providing insights into the root cause of component/material failure, establishing manufacturing quality control metrics and enforcing 3rdparty quality requirements. As numerous small, microscopic defects often lead to component failure, observing these factors on an extensive scale and assessing them in quantitative terms is the only way to formulate an accurate description that is needed for root cause analysis and determination (RCA).

Nanores Lab offers a range of tools for monitoring consistency, based on holistic identification and investigation of defects, faults, and failures. X-ray microtomography (microCT) is used for large volume analysis. This non-destructive technique generates 3D reconstructions of samples with micrometer resolution. With the core features identical to well-known hospital CAT scanning technology, microCT provides a practical overview of the material, allowing for identifying the location of defects and isolating them. Once identified, defects may be extracted and undergo more detailed analysis using higher-resolution techniques, such as electron microscopy (EM).

Deliverables

Contact Listings Owner Form

- Learn about who has visited this offer

- Get funding opportunities matching this technology

- Get detailed access statistics as listing owner