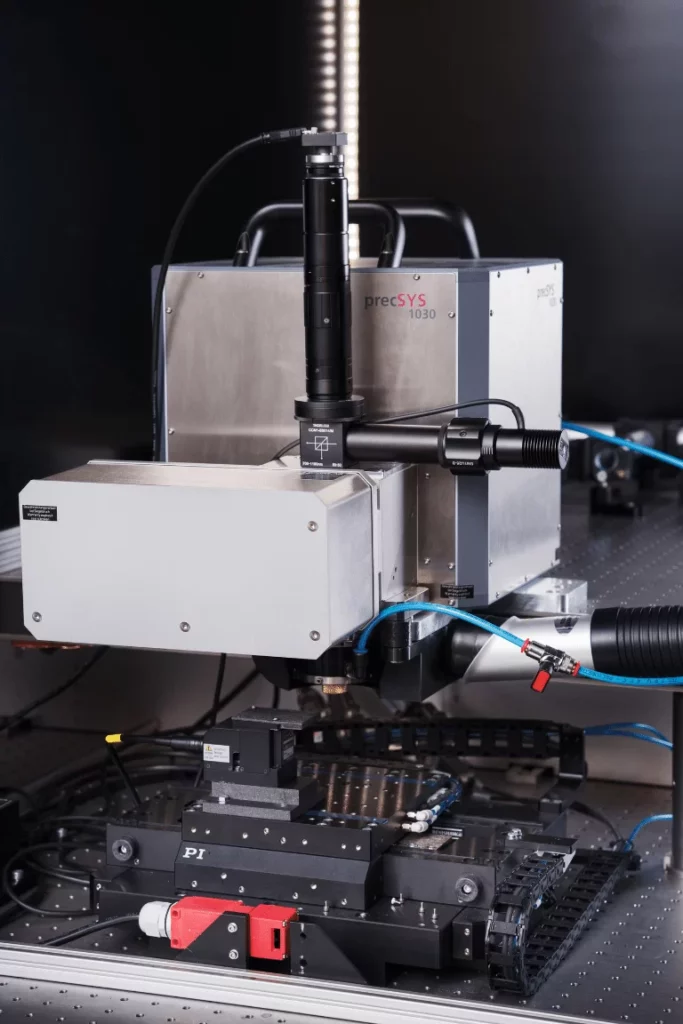

FEMTOSECOND LASER WORKSTATION

The unique laser workstation, constructed by the Nanores team using independent elements, features a femtosecond laser, a highly precise tool that is designed to tackle the challenges posed by advanced materials and complex mechanical designs.

Equipped with a five-axis scanning head, and a movable three-axis positioning system, this workstation is capable of producing parts previously deemed impossible, owing to several key features:

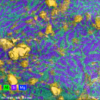

- ability to process every solid material

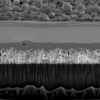

- thanks to the “cold” ablation technology, the loss of material occurs only where intended (zero waste), with minimal thermal effects

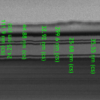

- cutting capability is possible in 5 axes (x, y, z, Alpha, Beta), facilitating the creation of intricate geometries

- ability to achieve aspect ratios of up to 1:10 in performed structures.

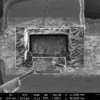

Its advantages include also the minimization of thermal interactions in the processed material, enabling exceptionally precise and clean work, without the need for additional processing. This makes it suitable for micro-processing, prototyping, and production of micro-components. Additionally, it finds extensive application in manufacturing micro-electromechanical systems (MEMS) and performing precise hole machining and cutting/moddification of elements.

Deliverables

– a part or base material that should be processed

– any additional quality requirements

– processing of micro-electro-mechanical systems (MEMS)

– precision hole machining

– precise cutting and modification of every solid material

1. Research:

– familiarizing with the material and the required geometry

– optimizing quality

2. Development:

– cost & time optimization

3. Production:

– implementing a scalable production process

All in consistency with customers internal processes.

Contact Listings Owner Form

- Learn about who has visited this offer

- Get funding opportunities matching this technology

- Get detailed access statistics as listing owner